TRAVELING SCREENS > SCM Channel Screen

INTRODUCTION:

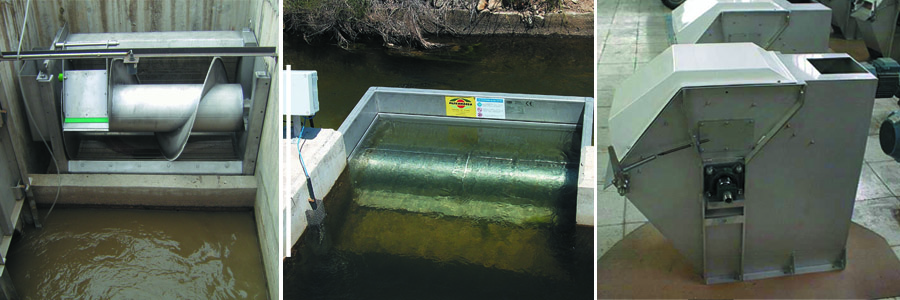

The SCM self-cleaning screen is a self-cleaning, single-flow, continuous travelling screen, adapted to work by extracting the solids in wastewater.

Unlike single flow band screens, which are common in large water intakes or irrigation systems, the SCM screen is designed to be installed in small and medium sized channels. The screen is designed to remove solids of a maximum size of 125 mm, so the installation must have appropriated previous protection.

DESCRIPTION:

The filtering band of the sieve is made up of teeth in the shape of a nose, made of ABS, connected to each other by means of stainless steel shafts. These shafts are connected to a roller conveyor chain with flange and hollow shafts, which drives the entire mechanism.

The operation of the equipment is very simple: The filter panels describe a curve in the lower part of the screen and, after passing through the lower horizontal seal, it traps the solids with the upper bevel of the panel. The solids are extracted from the bottom of the channel, and continuously lifted to the discharge point.

There is no relative movement between the high solids, and therefore it is not necessary to form a “filter pad” for the equipment to work properly. When it reaches the discharge point, the solids that do not adhere to the filter belt are discharged by gravity.

The filter panels open to each other and form a continuous curve without nooks and crannies. A scraper blade synchronized with the belt movement acts at the lowest point of the filtering rim, copying the profile of the curve formed by the open panels and expelling the solids adhered to the belt, as shown in the figure.

The SCM Channel Screen incorporates in all its models a washing tube with pressurized water. The sieve is driven by a geared motor.

APPLICATIONS:

-

Screening of urban and industrial wastewater.

-

Screening of raw water in pumping stations.

-

Separation of macroscopic algae in irrigation channels.

-

Screening of trawl water in vegetable canning industries.

-

Screening of discharges and process water in sugar factories.

-

Screening of effluent in the meat industry.

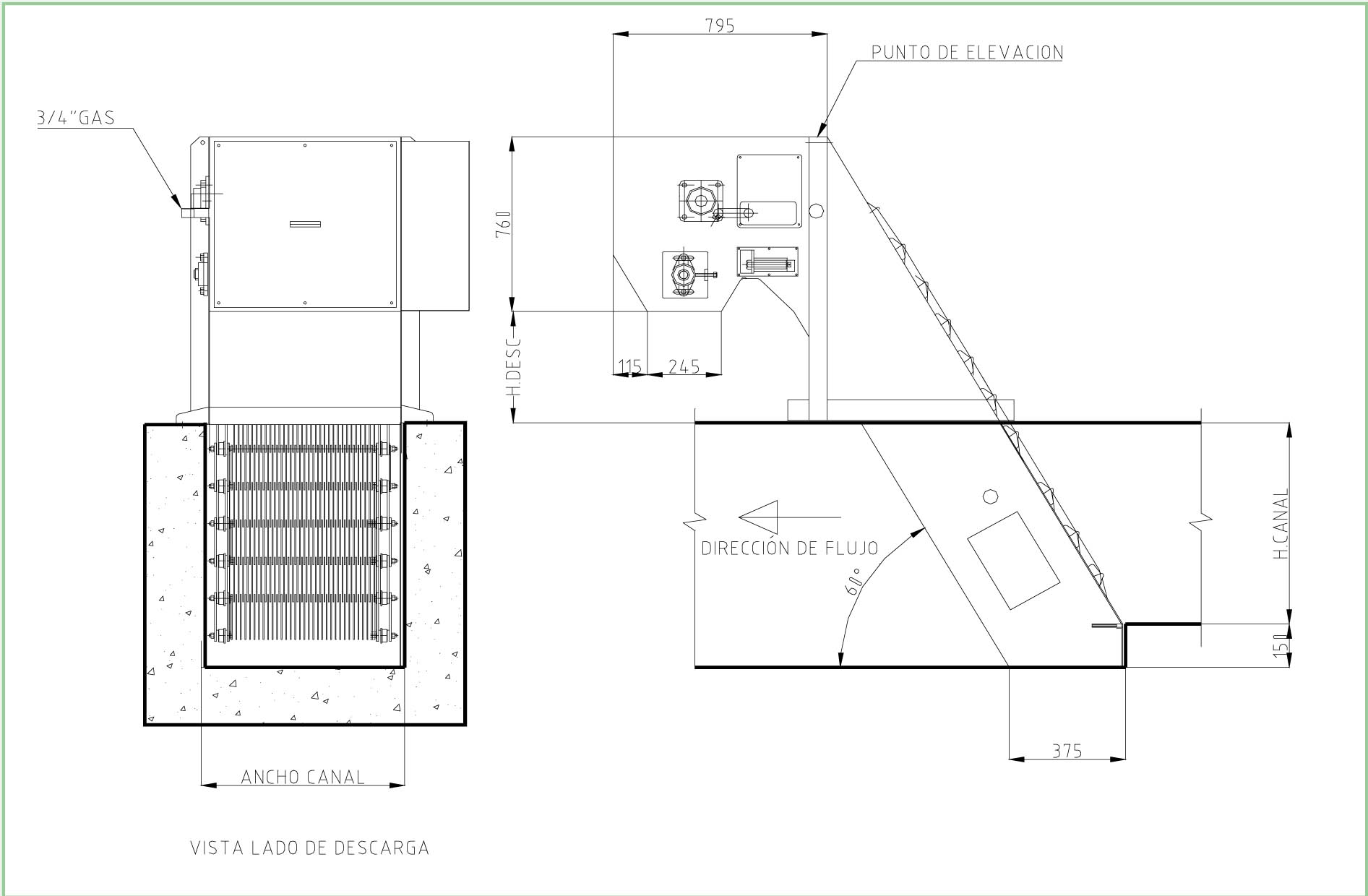

GENERAL DIMENSIONS:

|

CLIENTE |

CANT. |

PROYECTO |

| ABENSUR |

1 |

Paine (Chile) |

| ACCIONA AGUA |

1 |

EDAR EL QUIÑON |

| ACCIONA AGUA |

1 |

EDAR FORMENTERA |

| ACCIONA INFILCO |

3 |

ETAP TEMUCO |

| AGUAS FILTRADAS |

3 |

COLECTOR VIA CARPETANA |

| AGUAS FILTRADAS |

1 |

ERAR Humera |

| AGUAS FILTRADAS |

1 |

EDAR VIVEROS DE LA VILLA |

| AQUALIA (GESTION INTEGRAL DEL AGUA) |

1 |

MEJORAS EN LA EDAR DE GUIJUELO (SALAMANCA) |

| CONSTRUCCIONES SARRION |

2 |

EDAR LA SAGRA |

| CONSTRUCTORA SAN JOSE-ACCIONA |

2 |

EDAR ARANJUEZ NORTE (MADRID) |

| CONSTRUCTORA SAN JOSE |

2 |

COLECTOR EL PAULAR A OTERUELO DEL VALLE |

| COPISA |

1 |

EDAR Reinosa |

| DEGREMONT |

1 |

BREÑA BAJA Y LOS LLANOS |

| DINOTEC |

1 |

EDAR SATOCAN (LAS PALMAS DE GRAN CANARIA) |

| DINOTEC |

1 |

EDAR MONACHIL PRADOLLANO - SEVILLA |

| DRACE |

2 |

EDAR DE RICAO |

| DRACE-DETEA |

2 |

EDAR VERA |

| DRAGADOS |

1 |

CP ESTREMERA |

| DTD |

1 |

Carrión de los Céspedes (Sevilla) |

| DTD |

1 |

AMPLIACION PECC-CENTA |

| DTD |

11 |

EDARS ANDALUCIA |

| DTD |

1 |

EDAR'S Gergal |

| DTD |

1 |

EDAR'S Orcera |

| DTD |

1 |

Santa Barbara Sistemas |

| DTD |

1 |

DEP AGUAS RESIDUALES ORCE (GRANADA) |

| DTD |

1 |

EDAR DE GOR (GRANADA) |

| DTD |

1 |

EDAR´S ALMERIA |

| DTD |

1 |

EDAR´S ALMERIA |

| DTD |

1 |

COLECTOR Y EDAR DE ALOSNO / HUELVA |

| DYTRAS |

1 |

EDAR La Carolina / Jaen |

| DYTRAS |

2 |

EDAR´ S AVILA :CEBREROS |

| DYTRAS |

1 |

EDAR ARACENA |

| DYTRAS |

2 |

EDAR NAVALUENGA (AVILA) |

| DYTRAS |

2 |

EDAR EL TIEMBLO (AVILA) |

| ECOLOGIA CANARIA SANTA LUCIA |

2 |

ETAR Majadaciega |

| ECOPRENEUR |

1 |

Huasco |

| ECOPRENEUR |

4 |

CABULCO, FRUTILLAR |

| ECOPRENEUR |

3 |

Aguas Nuevo Sur |

| ECOPRENEUR |

2 |

Esval 3 pltas. |

| ECOPRENEUR |

1 |

PROYECTO CALAMA |

| ECOPRENEUR |

2 |

ESSAL |

| ECOPRENEUR |

1 |

Puerto Mont |

| ECOPRENEUR |

1 |

Mejoramiento Lagunas Salamanca |

| EDAR ALJORRA UTE |

2 |

EDAR ALJORRA |

| EDAR GUADALAJARA UTE |

3 |

Ampliación EDAR Guadalajara |

| EDAR MAIRENA UTE |

2 |

EDAR Mairena y Viso del Alcor |

| ELEUSIS INTERNACIONAL |

1 |

Matadero Picos de Europa |

| ELMASA |

1 |

Las Palmas |

| ETAP ABLANEDA UTE (AQUALIA) |

3 |

ETAP ABLANEDA |

| FCC CONSTRUCCION-AQUALIA |

3 |

EDAR VALDEPEÑAS (CIUDAD REAL ) |

| FERROVIAL-AGROMAN |

2 |

EDAR ALCALÁ DE HENARES |

| IMFLUID |

1 |

EDAR Sorihuela |

| IMFLUID |

1 |

EDAR POL. JUNCARIL-ASEGRA ALBOLOTE (GR) |

| INFILCO ESPAÑOLA |

2 |

P.T.A.S. LA LIGUA |

| INFILCO ESPAÑOLA |

5 |

EDAR Plaza (Zaragoza) |

| INFILCO ESPAÑOLA |

2 |

EDAR Almazán (Soria) |

| INIMA |

2 |

EDAR Abarán |

| INTAGSA |

1 |

EDAR Villa de Nefza (Túnez) |

| INTERSA |

2 |

EDAR Caravaca |

| IOMSAL |

1 |

EBAR FREMAP (MAJADAHONDA) |

| IOMSAL |

2 |

EDAR EL PASTEL Y EDAR LOS MOLINOS |

| MANCHA REAL UTE |

1 |

EDAR MANCHA REAL (JAEN) |

| MEYDE |

1 |

EDAR Montoro (Córdoba) |

| MP MEDIOAMBIENTE |

2 |

Snacks Venture Manufacturing |

| MP MEDIOAMBIENTE |

1 |

CARMONA / SEVILLA |

| MP SERVICIOS INDUSTRIALES |

1 |

EDAR DE EL CUERVO - SEVILLA |

| OSEPSA |

2 |

EDAR Pliego/Murcia |

| PASSAVANT-COPASA |

1 |

EMISARIO Y EDAR VILLABRAZARO (ZAMORA) |

| PASSAVANT-COPASA |

1 |

EMISARIO Y EDAR BOÑAR (LEÓN) |

| PRIDESA |

2 |

EDAR Cehegín |

| PRIDESA |

1 |

EDAR Órgiva |

| PRIDESA |

2 |

EDAR Utrera |

| PRIDESA |

1 |

EDAR SON SERRA |

| PRIDESA |

5 |

EDAR IBASAN |

| RICALSA |

1 |

Finca Osborne/Malpica del Tajo |

| RICALSA |

1 |

Regadio |

| RIEGOSUR |

2 |

EDAR Carmona |

| SETA |

1 |

EDAR METOUIA/TUNEZ |

| SETA |

2 |

AOUJSA (TUNEZ) |

| SITRA |

1 |

EDAR LES CARRASES, LLIRIA |

| SOCAMEX |

1 |

San Miguel de Salinas |

| SOCAMEX |

1 |

Bombeo Maldonado |

| SOCAMEX |

1 |

EDAR Villarcayo |

| SOCAMEX |

1 |

EDAR Guijuelo |

| SOCAMEX |

1 |

EDAR CP Soto del Real |

| SOCAMEX |

2 |

EDAR ISCAR |

| SOLUZIONA |

2 |

ACECA |

| SPA |

1 |

EDAR Monte Boyal |

| SPA |

2 |

UTE JARAMA LOZOYA |

| TECYMED |

1 |

EDAR Masia Bach |

| TECYMED |

2 |

EDAR VALLE DEL ZALABÍ |

| TRATAGUA |

1 |

EDAR Melilla |

| TRITIO |

1 |

CP ZUERA |

| TRITIO |

1 |

RUBIELOS DE MORA |

| TRITIO |

1 |

ZONA RECREATIVA BUITRAGO |

| UC-10 - DINOTEC |

1 |

EDAR TORREPEROGIL |

| UTE AMPLIACION EDAR LLEIDA |

4 |

AMLIACION EDAR LLEIDA (BARCELONA) |

| UTE COLLOSA-SOCAMEX |

2 |

EDAR ASTORGA (LEON) |

| UTE CONSTRUCTORA PEACHE |

1 |

EDAR MATAPOZUELOS |

| UTE CORONIL |

1 |

EDAR El Coronil |

| UTE CUENCA MEDIA |

9 |

Actuación X Canal Isabel II |

| UTE CUENCA RIO ALBERCHE |

1 |

EDAR San Martín de Valdeiglesias |

| UTE CUEVAS DEL CAMPO |

1 |

EDAR Cuevas del Campo (Granada) |

| UTE EDAR CABO PRIORIÑO |

4 |

EDAR CABO PRIORIÑO |

| UTE EDAR LOS PALACIOS |

2 |

UTE EDAR LOS PALACIOS |

| UTE EDAR OSUNA |

1 |

EDAR OSUNA |

| UTE EDAR TOMELLOSO |

4 |

EDAR TOMELLOSO - CIUDAD REAL |

| UTE RIO TAJUÑA |

6 |

Actuación VI Canal Isabel II |

| UTE TECNICAS REUNIDAS/TRIMTOR |

2 |

EDAR Torre de Cotillas |

| UTE TECNICAS REUNIDAS/TRIMTOR |

1 |

EDAR BARINAS (MURCIA) |

| UTE UICESA-DHA |

1 |

EDAR CENTRO PENITENCIARIO ALBOCASSER |

Band screens are those equipments, installed in a channel or , which has a series of filtering surfaces in continuous movement. Its mission is to extract the suspended solids of a certain size that accompany the effluent. There are several types of band screens, depending on the characteristics of the effluent and the installation:

Band screens are those equipments, installed in a channel or , which has a series of filtering surfaces in continuous movement. Its mission is to extract the suspended solids of a certain size that accompany the effluent. There are several types of band screens, depending on the characteristics of the effluent and the installation:

The objective of this equipment is to protect the WWTP or pumping well from the possible arrival of large objects capable of causing obstructions in the different units of the installation. This operation consists of passing the waste water through a screen that separates and evacuates the bulky materials dragged along. They will retain large-sized solids such as branches, leaves, paper, tree roots, plastics, wipes, rags, etc., preventing damage and blockages to pumps, valves, pipes and other elements present in subsequent treatment processes of the purification plant.

These devices allow to continue filtering while performing self-cleaning, being especially suitable for those applications where continuous filtering is an important parameter of the process. Filtramas recommends the installation of its FB or FW in-line filters according to the flow and filtration needs.

Filter sieves offer high performance in the solid-liquid separation process. Our range of equipment responds to the different possible needs for each case.

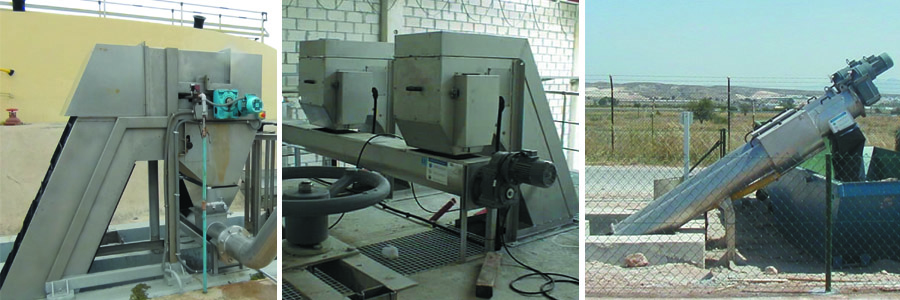

FILTRAMAS, S.A. has a wide range of solutions for the transport and compacting of the waste extracted by its machines, in a clean and discreet. The conveying and compacting systems can be with screws with final draining zone or hydraulic presses.

The conveyor-compactor screws supplied by FILTRAMAS, S.A., coupled together with its equipment, allow us to obtain a totally clean and fair-faced installation. The screw loading openings are designed for coupling to the discharge opening of the extraction equipment (bars movable grilles or screens), and the intermediate spaces are covered by a fairing.

In any water treatment or purification plant, there is a continuous need to isolate or regulate the flow of water in the channels and manholes or holes in walls (wall gates). This function is carried out by means of the placement of gates and cofferdams.

The result of our experience is the establishment of a standardization that determines a satisfactory result with a simple construction. For this reason, Filtramas has been developing the manufacture of penstocks and flashboards.

Filtramas manufactures channel hatches, wall hatches and cofferdams for different applications and uses.

The accumulation of solid waste in water treatment requires effective mechanized solutions for its extraction. FILTRAMAS, S.A. has a wide variety of equipment for the dragging of solid waste.

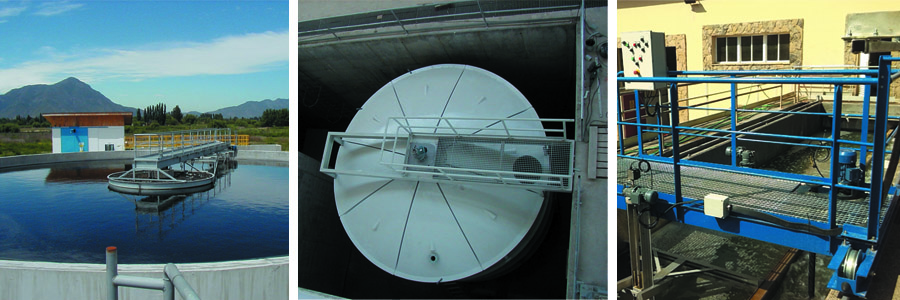

In the biological treatment of wastewater, a series of processes are generated based on the cultivation of bacterial microorganisms for the elimination of organic matter, nitrogen and phosphorus. It is one of the most common treatments for its simplicity and low cost.

FILTRAMAS, S.A. has a wide variety of equipment for bacterial culture applied to the treatment of urban and industrial wastewater.

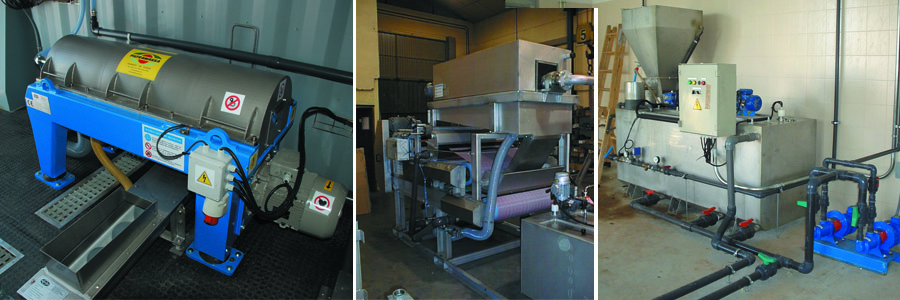

The dewatering of sludge is an essential process in the management of solid waste generated in water treatment. FILTRAMAS, S.A. offers different mechanized solutions to the problem according to the different possible needs.

FILTRAMAS S.A. has a wide variety of solutions for all kinds of problems associated with the treatment and cleaning of water, mud and sand. We develop our specialisation on the basis of the experience accumulated by our professionals, constant effort and close collaboration with our clients. FILTRAMAS S.A. perfects new products, looking for economic and effective solutions. Any problem that arises in the handling of fluids is carefully analyzed in order to find an economically balanced solution.