IN-LINE FILTERS > Self-cleaning filter FB

INTRODUCTION:

The self-cleaning filter FB is a very versatile and easy to install device designed for the removal of solids from 0.1 mm in pressure pipe circuits. These devices allow to continue filtering at the same time as self-cleaning; they are especially suitable for those applications where continuous filtering is an important parameter of the process.

DESCRIPTION:

They are usually used to filter treated process and cooling water. The filter can operate in continuous or intermittent mode depending on the application. Once the fluid to be filtered has been characterized, the mesh size is selected with the largest possible dimension; for example, if the FB Filter is to be used as protection for another element, the pass light should be half the smallest hole to protect.

The fluid to be filtered is led to the central space of the filter, limited in all its surroundings by a basket that holds the filtering element: mesh or perforated plate in AISI-304 or 316, coming out through it by the opposite flange. The solids retained by the filter screen are sucked in by the hollow rotating arm, equipped with a sweeping skid, and evacuated by the backwash effect, exiting to the outside through the central axis. The arm movement is achieved by a gear motor of suitable power. The output to the outside of the shaft to couple to the gearmotor is sealed by a cable gland.

The FB filter can be operated continuously or intermittently, depending on the nature and concentration of solids contained in the fluid to be treated. In the case of intermittent operation, the filter incorporates an automatic purge valve placed in the drain. This valve can be activated by a timer system or a differential pressure unit, with two indicators placed at the inlet and outlet respectively. However, we recommend its use in timed mode, combined with the differential pressure system that would activate an emergency flushing in the event of an unforeseen volume of solids clogging the screen.

FB Self-Cleaning Filters have the following advantages:

-

Continuous operation due to its continuous cleaning system does not require process stops for backwashing.

-

Low operating cost due to the low electrical power used.

-

Minimum rejection rate.

-

Low maintenance cost due to few components subject to wear; simple disassembly operations.

-

Optimized dimensions for high flow rates.

-

SELF CLEANER FILTER.

FB self-cleaning filters are specially designed for the demanding filtration of high flow rates in municipal and industrial applications.

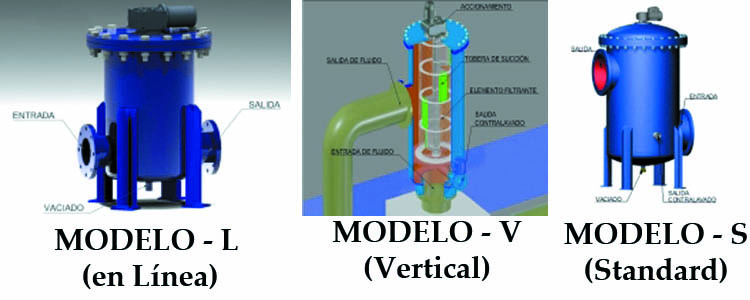

FILTRAMAS S.A. has the following models available:

- Model W (wedge profile): It consists of a robust stainless steel cylinder in the form of a cage covered with triangular wire welded to the support. The solids have only two contact points, which prevents clogging during backwashing. The filter is very robust and has a long service life.

- Model P (pleated basket): The filtering cylinder is provided with folds that multiply the available filtering surface and provide spaces for solids accumulation, thus avoiding its dragging along the cleaning skate.

-

Model C (cylindrical basket): The cylindrical filter screen is fixed to an inner cage, which can be made of stainless steel, bronze or plastic.

APPLICATIONS:

- Paper industry

- Metallurgical industry

- Food industry

- Textile industry

- Chemical industry

- Mining industry

- Energy production plants

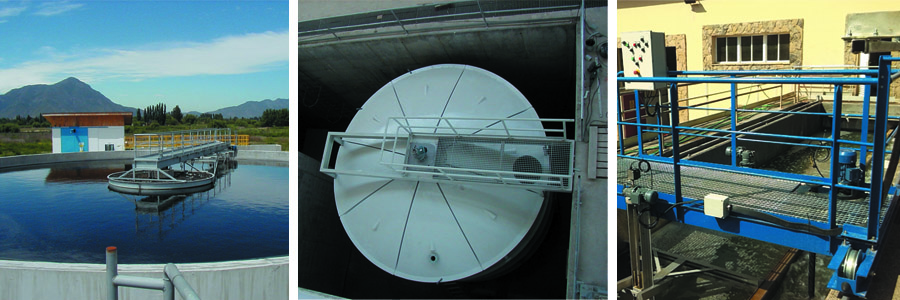

- Wastewater treatment (urban and industrial)

- Heat exchangers

- Bearing cooling.

- Cooling in steel mills.

- General nozzle protection.

- Service water.

- Pretreatment for microfiltration.

- Sprinkler irrigation.

- Drinking water intakes from wells and rivers.

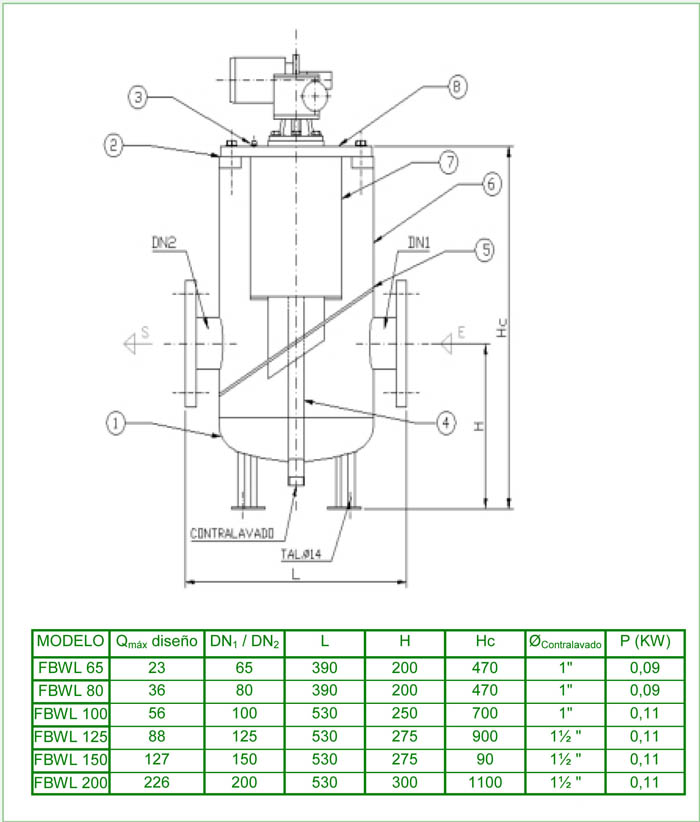

GENERAL DIMENSIONS:

-

Wide range of sizes from DN65, DN80, DN80,… to DN800, depending on the application and the flow rate to be treated.

-

Large number of passing lights from 100µ to 3000µ.

Model FB W L

|

CLIENTE / CUSTOMER |

CANT./QTY |

PROYECTO / PROJECT |

| ABENSUR |

4 |

EDAR Las Cabezas de San Juan |

| ACCIONA AGUA |

1 |

EDAR PAZARDJIL (BULGARIA) |

| ASTURCONTROL |

2 |

--- |

| BEKOX |

2 |

EDAR Tías |

| CADAGUA |

1 |

EDAR Guadarrama |

| CADAGUA |

1 |

EDAR Ribes |

| CADAGUA |

1 |

EDAR L'Horta Nord |

| CAMPING EL ESCORIAL |

1 |

Depuradora |

| CERVEZAS EL AGUILA |

1 |

--- |

| CIDA-HIDROQUIMICA |

3 |

Tres Cantos |

| CIDA-HIDROQUIMICA |

1 |

Riosequillo |

| CIDA-HIDROQUIMICA |

1 |

Camp de Turia |

| CIDA-HIDROQUIMICA |

1 |

EDAR Robledo de Chavela |

| CIDA-HIDROQUIMICA |

1 |

EDAR Sallent |

| DEGREMONT |

1 |

San Feliu |

| DEGREMONT |

2 |

Resi-Soria |

| DEGREMONT |

1 |

Torroella |

| DEIDA |

1 |

--- |

| DINOTEC |

1 |

EDAR Torredelcampo |

| DINOTEC |

1 |

EDAR Valle del Gran Rey |

| DINOTEC |

1 |

EDAR Playa de Santiago |

| DINOTEC |

1 |

EDAR Estepa |

| DRACE |

2 |

Murcia |

| DRAGADOS Y CONST. |

1 |

EDAR San Martin |

| DRAGADOS Y CONST. |

1 |

EDAR Aranjuez |

| DRAGADOS Y CONST. |

1 |

EDAR Montcada |

| DRAGADOS Y CONST. |

2 |

EDAR Navalcarnero |

| DRAGADOS Y CONST. |

1 |

EDAR Sanlucar Barrameda |

| DRAGADOS Y CONST. |

1 |

EDAR Sta. Coloma |

| DRAGADOS Y CONST. |

2 |

EDAR Llagosta |

| DRAGADOS Y CONST. |

1 |

EDAR Llanes |

| DRAGADOS Y CONST. |

1 |

EDAR Castellon |

| DRAGADOS Y CONST. |

1 |

EDAR Pontón Alto |

| DRAGADOS Y CONST. |

1 |

Villafranca del Penedes |

| DRAGADOS Y CONST. |

1 |

Cambrils |

| DRAGADOS Y CONST. |

1 |

--- |

| DYTRAS |

4 |

EDAR BELMEZ (CORDOBA) |

| DYTRAS |

2 |

EDAR ESPIEL |

| DYTRAS |

4 |

EDAR CASARRUBIOS DEL MONTE (TOLEDO) |

| DYTRAS |

4 |

EDAR CHOZAS DE CANALES (TOLEDO) |

| DYTRAS |

2 |

EDAR ALAMEDA (MALAGA) |

| DYTRAS |

2 |

EDAR THARSIS / HUELVA |

| ECOLOGIA CANARIA STA LUCIA |

1 |

ETAR Majadaciega |

| EMC REJAS |

1 |

Rejas |

| ENDESA |

2 |

C.H. Santamarina |

| ENDESA |

1 |

Escatron |

| ENFECSA |

1 |

Arganda |

| FCC |

1 |

EDAR Cabezón de la Sal |

| FOCSA (FCC) |

1 |

EDAR Fuente el Saz |

| FOCSA (FCC) |

1 |

Lugo |

| FOCSA (FCC) |

1 |

Alcoy |

| FOCSA (FCC) |

1 |

Valdemoro/ciempozuelos |

| FOCSA (FCC) |

2 |

EDAR Cordoba |

| FOCSA (FCC) |

1 |

EDAR Fuente el Saz |

| FOCSA (FCC) |

1 |

EDAR Sada |

| FOCSA (FCC) |

2 |

EDAR Tarragona |

| FOCSA (FCC) |

1 |

EDAR Abrera |

| FOCSA (FCC) |

1 |

EDAR Tarrega |

| FOCSA (FCC) |

1 |

EDAR Granada Sur |

| FOCSA (FCC) |

1 |

Figueras |

| GRAVER ESPAÑOLA |

3 |

Proyecto Sabón-Socoin |

| GTT INGENIERIA |

1 |

EDAR DE BENFERRI |

| HEYMO INGENIERIA |

2 |

Terquimsa |

| IBERDROLA |

4 |

G-H- Cedillo / Cáceres |

| IBERDROLA |

3 |

C.H. Valdecañas |

| IMFLUID |

1 |

|

| INCOME |

2 |

|

| INFILCO ESPAÑOLA |

1 |

Colmenar |

| INFILCO ESPAÑOLA |

1 |

Puertollano |

| INFILCO ESPAÑOLA |

1 |

Canarias |

| INFILCO ESPAÑOLA |

1 |

Besos |

| INFILCO ESPAÑOLA |

1 |

Alcan |

| INFILCO ESPAÑOLA |

1 |

EDAR Lepe |

| INFILCO ESPAÑOLA |

2 |

--- |

| INFILCO ESPAÑOLA |

2 |

EDAR Rubi |

| INFILCO ESPAÑOLA |

2 |

EDAR Torrente |

| INFILCO ESPAÑOLA |

2 |

DESPLA. |

| INFILCO ESPAÑOLA |

2 |

EDAR Benicasim |

| INFILCO ESPAÑOLA |

2 |

EDAR Calafell |

| INFILCO ESPAÑOLA |

1 |

Venta de Baños |

| LOECHES UTE |

1 |

EDAR Loeches |

| MECANICA LA PEÑA |

1 |

C.H. Zudaire |

| OCISA |

1 |

Arcos de la Frontera |

| OCISA |

1 |

La Poveda |

| OCP |

2 |

EDAR Denia |

| OCP |

1 |

Vilanova y la Geltrú |

| ONDEL INDUSTRIAL SOLUTIONS |

2 |

CC Aceca Soluziona |

| ORTIZ CONSTRUCCIONES |

1 |

Edar Cobeña |

| PRIDESA |

2 |

Mortornés |

| PRIDESA |

1 |

EDAR Piera |

| PRIDESA |

1 |

EDAR Osorno |

| PRIDESA |

1 |

ETAR Peso da Régua |

| PRIDESA |

1 |

ETAR Mutela |

| PRIDESA |

1 |

EDAR Cunit |

| PRIDESA |

2 |

EDAR Guadalhorce |

| PRIDESA |

1 |

EDAR Fraga |

| PROYMINSA |

2 |

Valca. |

| SACIR |

1 |

Ejea de los Caballeros |

| SADYT |

1 |

EDAR BURGUILLOS |

| SADYT |

1 |

EDAR POLAN |

| SADYT |

2 |

EDAR DE MELILLA |

| SETA |

1 |

|

| SOCAMEX |

1 |

EDAR SOLLER |

| SPA |

2 |

EDAR San Feliu |

| SPA |

1 |

Velilla de San Antonio |

| SPA |

1 |

Orihuela. |

| SPA |

2 |

ETAR Aveiro norte |

| SPA |

2 |

EDAR Jaen |

| SPA |

4 |

ACT. II Cuenca Ríos Jarama-Lozoya |

| SPA |

2 |

Mar Menor-Sur |

| SPA |

2 |

EDAR El Espinar |

| TECNICAS REUNIDAS |

1 |

Majadahonda |

| TECNICAS REUNIDAS |

1 |

Aceria Wuhan (China) |

| TECNICAS REUNIDAS |

1 |

Cartagena |

| TRITIO |

1 |

EDAR Salamanca |

| U.T.E. NECSO-PRIDESA |

2 |

EDAR León |

| U.T.E. OCP-ABENGOA |

1 |

EDAR Motril |

| USF BEKOX |

1 |

EDAR Barranco Seco |

| UTE CIDA HIDROQUIMICA/OCISA |

1 |

EDAR Ripoll |

| UTE COPISA INFILCO |

1 |

EDAR Valls |

| UTE EDAR LAZAROTE |

2 |

EDAR Playa Blanca |

| UTE EDAR VALLS |

1 |

EDAR Valls |

| UTE JOCA/INIMA |

2 |

Torrox (Málaga). |

| UTE LA GAVIA |

1 |

EDAR La Gavia |

| UTE OCP/PRIDESA |

2 |

EDAR Adeje-Arona |

| UTE PAS-SPA |

1 |

EDAR Arenas de San Pedro |

| UTE RIEGOS PIRACES |

1 |

COMUNIDAD DE REGANTES PIRACES (HUESCA) |

| UTE SOSES |

1 |

Comunidad Regantes Aragón |

| UTE SPA-FCC |

1 |

Rincón de León |

These devices allow to continue filtering while performing self-cleaning, being especially suitable for those applications where continuous filtering is an important parameter of the process. Filtramas recommends the installation of its FB or FW in-line filters according to the flow and filtration needs.

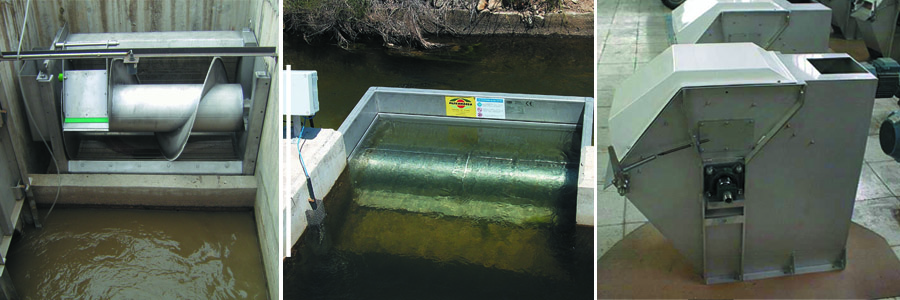

Band screens are those equipments, installed in a channel or , which has a series of filtering surfaces in continuous movement. Its mission is to extract the suspended solids of a certain size that accompany the effluent. There are several types of band screens, depending on the characteristics of the effluent and the installation:

The objective of this equipment is to protect the WWTP or pumping well from the possible arrival of large objects capable of causing obstructions in the different units of the installation. This operation consists of passing the waste water through a screen that separates and evacuates the bulky materials dragged along. They will retain large-sized solids such as branches, leaves, paper, tree roots, plastics, wipes, rags, etc., preventing damage and blockages to pumps, valves, pipes and other elements present in subsequent treatment processes of the purification plant.

These devices allow to continue filtering while performing self-cleaning, being especially suitable for those applications where continuous filtering is an important parameter of the process. Filtramas recommends the installation of its FB or FW in-line filters according to the flow and filtration needs.

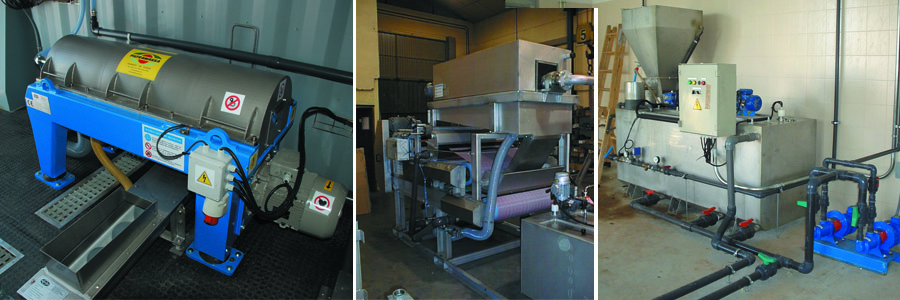

Filter sieves offer high performance in the solid-liquid separation process. Our range of equipment responds to the different possible needs for each case.

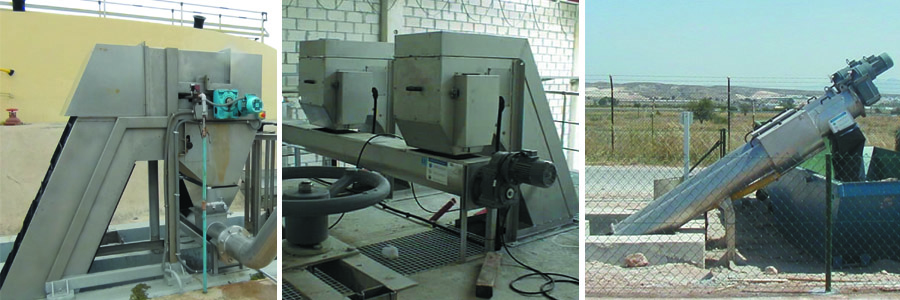

FILTRAMAS, S.A. has a wide range of solutions for the transport and compacting of the waste extracted by its machines, in a clean and discreet. The conveying and compacting systems can be with screws with final draining zone or hydraulic presses.

The conveyor-compactor screws supplied by FILTRAMAS, S.A., coupled together with its equipment, allow us to obtain a totally clean and fair-faced installation. The screw loading openings are designed for coupling to the discharge opening of the extraction equipment (bars movable grilles or screens), and the intermediate spaces are covered by a fairing.

In any water treatment or purification plant, there is a continuous need to isolate or regulate the flow of water in the channels and manholes or holes in walls (wall gates). This function is carried out by means of the placement of gates and cofferdams.

The result of our experience is the establishment of a standardization that determines a satisfactory result with a simple construction. For this reason, Filtramas has been developing the manufacture of penstocks and flashboards.

Filtramas manufactures channel hatches, wall hatches and cofferdams for different applications and uses.

The accumulation of solid waste in water treatment requires effective mechanized solutions for its extraction. FILTRAMAS, S.A. has a wide variety of equipment for the dragging of solid waste.

In the biological treatment of wastewater, a series of processes are generated based on the cultivation of bacterial microorganisms for the elimination of organic matter, nitrogen and phosphorus. It is one of the most common treatments for its simplicity and low cost.

FILTRAMAS, S.A. has a wide variety of equipment for bacterial culture applied to the treatment of urban and industrial wastewater.

The dewatering of sludge is an essential process in the management of solid waste generated in water treatment. FILTRAMAS, S.A. offers different mechanized solutions to the problem according to the different possible needs.

FILTRAMAS S.A. has a wide variety of solutions for all kinds of problems associated with the treatment and cleaning of water, mud and sand. We develop our specialisation on the basis of the experience accumulated by our professionals, constant effort and close collaboration with our clients. FILTRAMAS S.A. perfects new products, looking for economic and effective solutions. Any problem that arises in the handling of fluids is carefully analyzed in order to find an economically balanced solution.