WASTE COMPACTING CONVEYORS > Screw Conveyors TT and TP

INTRODUCTION:

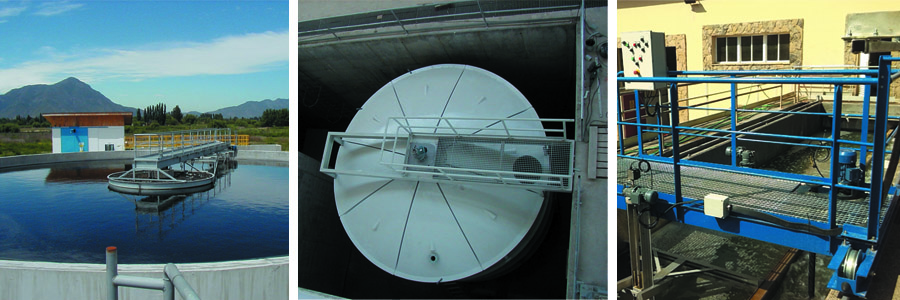

In all wastewater treatment plants, treatment plants, pumping stations, etc., a grinding process is carried out to generate waste. The amount of waste roughened will depend directly on the clearance of the equipment used for this function and on the dimensions of the transport manifolds.

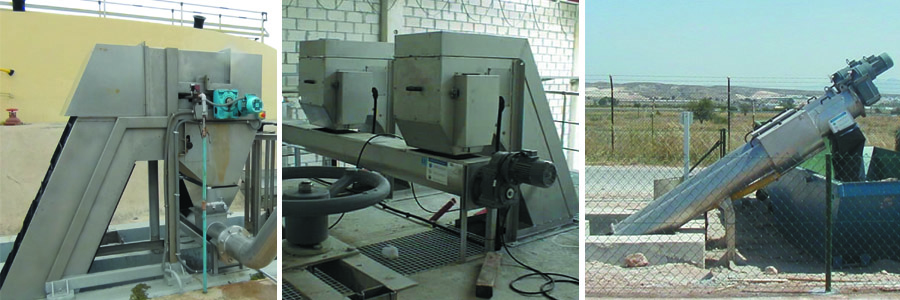

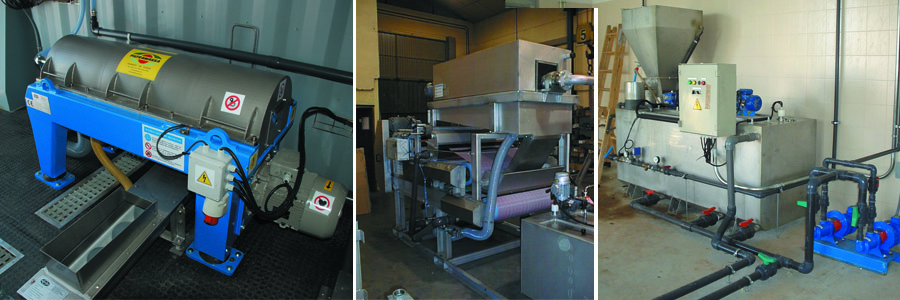

The dry matter content of roughing residues in urban water is between 10-25%, depending on the sieving process, and the organic content can be up to 90%. The transport system, by means of a screw conveyor-compactor of waste TP, is a clean and efficient method for the evacuation of solids coming from fine grinding (screens and sieves), replacing the conventional conveyor belts for their cleaning, less height required and their capacity to drain the waste before it is unloaded into the container.

DESCRIPTION:

The operation of this equipment is very simple. The drive gear motor performs a rotating action on the conveyor propeller, which slides on the sliding sleeve and involves a forward movement of the solids that have penetrated into the screw press. The water drained in the pressure jacket is channelled to an outlet pipe installed for this purpose. The conveyor propeller deposits the solids inside the filter jacket, where the pressing action is carried out. The pressure control is carried out by means of a mechanical system that controls the opening of a flap, before discharging into a container.

Its design is based on the rotation of a worm screw without shaft. This shaftless spiral has a higher conveying capacity as it is less sensitive to fibrous matter, which tends to agglomerate and can thus transport waste with a wide range of granulometry. The screw can be operated by “pulling” or “pushing”.

Optionally, the body can be fitted with a draining box at the bottom of the rear, under a section of gutter in which perforated sheet metal is installed. This perforated plate is cleaned by the propeller using an auxiliary brush mounted on the edge of the screw. This configuration is especially recommended for inclined screws.

The body, legs and clamping head are made of stainless steel. The sliding cradle is manufactured with high density polyethylene sheet… The propeller is cold formed from plates. It is usually manufactured in high resistance carbon steel ST-52, being feasible the supply in AISI-304 or AISI-316L. Our teams have the following FEATURES:

- Sizing of the equipment according to the characteristics of each installation.

- Cradles made with different sections: circular or half round.

- Transport of the roughing residue.

-

Compaction reduces the volume of waste to be managed and also reduces operating costs.

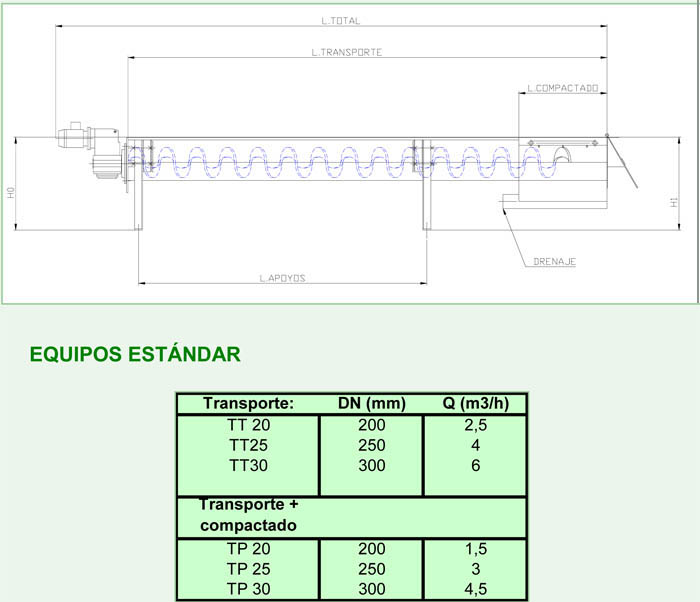

GENERAL DIMENSIONS:

|

CLIENTE |

CANT. |

PROYECTO |

| ABENER |

2 |

Sangüesa/NAVARRA |

| ABENSUR |

3 |

EDAR Los Villares |

| ABENSUR |

1 |

EDAR Navalcarnero |

| ABENSUR |

2 |

EDAR El Vellón, El Molar, ... |

| ABENSUR |

1 |

Paine/Chile |

| ACCIONA AGUA |

1 |

EDAR DE CASAREJOS (SORIA) |

| Acuaestudios-Viacron UTE |

3 |

EDAR Binefar/Huesca |

| ADE BIOTEC |

1 |

|

| AENA |

1 |

|

| AGRICULTORES DE LA VEGA |

1 |

EDAR Font de la Pedra |

| AGUA Y MEDIOAMBIENTE |

1 |

EDAR Brieva/Avila |

| AGUAS FILTRADAS, S.A. |

3 |

EDAR Viveros de la Villa |

| ALCEDAR |

1 |

Alcorisa |

| AMBIENTALIA LEVANTE S.L. |

1 |

EDARI POSTRE REINA (CARAVACA) |

| AQUAFRISCH SL |

1 |

CTT MALAGA |

| AQUAFRISCH SL |

1 |

CTT DE ALTA VELOC. DE FUENCARRAL (MADRID) |

| AQUAFRISCH SL |

1 TP-2020 |

TALLER CORNELLA (BARCELONA) |

| AQUAGEST LEVANTE |

1TP-2050 |

EDAR ALMORADI (ALICANTE) |

| AQUAGEST MEDIOAMBIENTE |

1 TP-2020 |

EDAR AEROPUERTO DE GERONA |

| AQUAGEST MEDIOAMBIENTE |

1 TT-2040 |

EDAR AEROPUERTO DE GERONA |

| ASTEISA |

1 |

|

| ASTEISA |

1 |

EDAR Veigue |

| ASTEISA |

1 |

EDAR Veigue/A Coruña |

| ATM |

1 |

EDAR TARAMUNDI |

| CADAGUA |

2 |

EDAR Castellón |

| CADAGUA |

1 |

EBAR GALICA (MALAGA) |

| CANAL ISABEL II |

1 |

El Endrinal (Villalba) |

| CONSORCIO AGUAS DE MALAGA |

1 |

EDAR CANILLAS DE ACEITUNO (MALAGA) |

| CONSTRUCCIONES RAYET-SOCAMEX |

1 |

EDAR VILLAGARCIA |

| CONSTRUCCIONES RAYET-SOCAMEX |

1 |

EDAR LEDAÑA |

| CONSTRUCCIONES RAYET-SOCAMEX |

1 |

EDAR MINGLANILLA |

| CONSTRUCCIONES RAYET-SOCAMEX |

1 |

EDAR VILLART |

| CONSTRUCCIONES SANDO |

1 |

EDAR La Cabrera |

| CONSTRUCCIONES SARRION |

8 |

EDAR'S Calatrava |

| CONSTRUCCIONES SARRION |

2 TP-2040 |

EDAR LA SAGRA |

| CONSTRUCTORA SAN JOSE - ACCIONA |

2 |

EDAR ARANJUEZ NORTE (MADRID) |

| CONSTRUCTORA SAN JOSE |

1 |

URB. LA MAQUINILLA DE COLMENAR VIEJO |

| CONSTRUCTORA SAN JOSE |

1 TP-2040, 1 TP-2078, 1 TP-2035 |

COLECTOR EL PAULAR A OTERUELO DEL VALLE T.M. RASCAFRIA |

| CONTRATAS LA MANCHA S.A. |

1 |

EDAR CAUDETE (ALBACETE) |

| DEGREMONT |

4 |

EDAR Sur Oriental |

| DEGREMONT |

2 |

EDAR Algemesí |

| DEGREMONT |

2 |

EDAR Sureste |

| DEGREMONT |

2 |

EDAR Vinaroz |

| DEGREMONT |

1 |

EDAR ORDUÑA |

| DEMAIN |

1 TP 2020, 1 TP 2040 |

EDAR ESTEIRO-MUROS |

| DAM |

1 |

EDAR ALEGRIA (ALAVA) |

| DAM |

1 |

EDAR DE SALVATIERRA |

| DAM |

1 TT-2060 |

EDAR ARAIA - ÁLAVA |

| DEPUMASTER |

2 |

EDAR Ubrique |

| DINOTEC SAMA |

1 |

COMPLEJO MEDIO AMBIENTAL ARICO |

| DRACE MEDIOAMBIENTE |

1 TP-2045 |

EDAR EL ESPARTAL (MADRID) |

| DRACE MEDIOAMBIENTE |

1 TP-2030 |

EDAR ROBLEDILLO |

| DRACE MEDIOAMBIENTE |

1 TP-2030 |

EDAR BERZOSA |

| DRAGADOS |

1TP 2040 |

CP ESTREMERA (MADRID) |

| DRAGADOS |

1TP 2020 |

CP ESTREMERA (MADRID) |

| DRAGADOS |

1TP 2060 |

CP ESTREMERA (MADRID) |

| DTD |

2 TP-2030 |

COLECTOR Y EDAR DE ALOSNO / HUELVA |

| DTD |

2 TP-2030 |

EDAR CASTELLAR DE LA FRONTERA Y ALMORAIMA |

| DYTRAS |

1 |

EDAR Medina Sidonia |

| DYTRAS |

1 |

EDAR´S AVILA:EL BARRACO |

| DYTRAS |

1 |

EDAR HOYO DE PINARES (AVILA) |

| DYTRAS |

1 |

EDAR BELMEZ (CORDOBA) |

| DYTRAS |

1 |

EDAR ESPIEL (CORDOBA) |

| DYTRAS |

1 |

EDAR BELALCAZAR |

| DYTRAS |

1 TP 2035 |

EDAR´S AVILA: CEBREROS |

| DYTRAS |

1 TP-2080 |

EDAR PRIEGO/CORDOBA |

| DYTRAS |

1 TP-2035 |

EDAR NAVALUENGA (AVILA) |

| DYTRAS |

1 TT-2040 |

EDAR NAVALUENGA (AVILA) |

| DYTRAS |

1 TP-2030 |

EDAR ALAMEDA (MALAGA) |

| DYTRAS |

1 TP-2035, 1 TT-2040 |

EDAR EL TIEMBLO (AVILA) |

| DYTRAS |

1 TT-2042 |

EDAR THARSIS / HUELVA |

| ECOPRENEUR |

1 |

EDAR Traiguén y Lumaco |

| ECOPRENEUR |

2 |

HUASCO |

| EDAR ARRUBAL Y AGONCILLO |

4 |

EDAR Arrubal y Agoncillo |

| EMPRESA MIXTA DE AGUAS DE LA COSTA BRAVA |

2 |

EMACB |

| EPTISA |

1 TP-2030 |

EDAR CUIÑA |

| ESPINA OBRAS HIDRAULICAS |

1 TT-2565, 1 TT-2545, 2 TT-2566 |

CIUDAD DE LA COSTA (URUGUAY) |

| ETAP ABLANEDA UTE (AQUALIA) |

3 |

ETAP ABLANEDA |

| FACSA |

1 TT-2040 |

EDAR VILLAFRANCA |

| FACSA |

1 TT-2040 |

EDAR DE MORELLA |

| FACSA |

1 TT-2050 |

EDAR TERUEL |

| FCC CONSTRUCCION |

1 |

EBAR CANET DE BERENGUER - VALENCIA |

| FCC CONSTRUCCION |

1 TP-2060 |

AMPLIACION EDAR CAMPO REAL |

| FCC-SPA |

3 |

EDAR Rejas |

| FERROVIAL-AGROMAN |

1 TP-2050 |

EDAR ALCALÁ DE HENARES |

| GIA GRUPO EP |

1 |

EDAR Briviesca |

| GRUPO GENERALA |

2 |

HACIENDA RIQUELME |

| GRUTECONSA |

3 |

Quintanar de la Sierra |

| GRUTECONSA |

1 |

EDAR Marinaleda |

| HIDROTEC |

1 TP-2010 |

CANARIAS |

| HISPANAGUA |

1 TP-2060 |

EDAR EL VELLÓN |

| IMFLUID S.L. |

2 |

EDAR POL. JUNCARIL-ASEGRA ALBOLOTE (GR) |

| INFILCO ESPAÑOLA, S.A. |

1 |

P.T.A.S. La Ligua |

| IOMSAL |

1 |

EBAR MAJADAHONDA |

| IOMSAL |

1 TP-2050 |

EDAR EL PASTEL Y EDAR LOS MOLINOS |

| ISOLUX WAT |

1 |

EDAR Herencia |

| ISOLUX WAT |

1 |

EDAR Viella/Lérida |

| ISOLUX WAT |

2 |

EDAR Villaconejos |

| ISOLUX WAT |

2 |

EDAR Calasparra |

| JOCA |

2 |

EDAR Corralejo/Las Palmas |

| JOCA |

1 TT-2040, 1 TT-2070 |

EMISARIO LAGUNA DE DUERO - VALLADOLID |

| MANCHA REAL UTE |

2 TP-2030 |

EDAR MANCHA REAL |

| MP SERVICIOS INDUSTRIALES |

1 TP-2025, 1 TP-2015 |

EDAR DE EL CUERVO - SEVILLA |

| M&OP (MONTAJES Y OBRAS PUBLICAS) |

1 TP-2020 |

SIMANCAS (VALLADOLID) |

| OCIDE CONSTRUCCIONES SA |

1 TP-2040 |

EDAR ALBAIDA |

| ORTIZ CONSTRUCCIONES |

1 |

Edar Cobeña |

| OSEPSA |

2 |

EDAR Pliego/Murcia |

| PACSA |

1 TT-2035 |

PARQUE ARROYO DE LA GAVIA |

| PASSAVAN ESPAÑA S.A. |

1 |

AMPLIACIÓN EDAR MANLLEU |

| PASSAVANT ESPAÑA S.A. |

1 |

PORTO DO SON |

| PASSAVANT ESPAÑA S.A. |

1 TT-2590, 1 TT-2038, 1 TP 2520 |

EDAR BAIONA (PONTEVEDRA) |

| PASSAVANT-COPASA |

2 |

EMISARIO Y EDAR VILLABRAZARO (ZAMORA) |

| PASSAVANT-COPASA |

1 |

EMISARIO Y EDAR BOÑAR (LEÓN) |

| PRIDESA |

1 |

Alto Urola |

| PRIDESA |

1 |

EDAR Almoradi/Alicante |

| PRIDESA |

1 |

EDAR Bergara |

| SACYR |

1 TT-2030 |

URBANIZACION EL JUNCAL (ALCOBENDAS) |

| SADYT |

1 |

EDAR BURGUILLOS |

| SADYT |

1 |

EDAR POLAN |

| SAICO/INTAGUA |

1 |

EDAR Tavernes |

| SAINCO UTE |

1 |

EDAR Orihuela |

| SEARSA |

2 |

EDAR Crispijana/Vitoria |

| SEARSA |

2 |

Cadaques y Colera |

| SEARSA |

2 |

Palamos |

| SIX CONSTRUCTORES |

2 |

EDAR Sector CM3 VILAMALLA |

| SOCAMEX, S.A. |

1 |

EDAR S. Miguel de Salinas |

| SOCAMEX, S.A. |

1 |

EDAR Guijuelo |

| SOCAMEX, S.A. |

2 |

Bombeo Maldonado |

| SOCAMEX, S.A. |

1 |

PUIGPUNYENT |

| SPA |

1 |

Aer. de Lanzarote |

| SPA, S.A. |

1 |

EDAR Callosa del Segura |

| SPA, S.A. |

1 |

EDAR Tarragona |

| SPA. |

1 |

EDAR Casablanca/Marruecos |

| TECVASA |

1 |

EDAR LORIGUILLA |

| TECVASA |

1 |

EDAR LORIGUILLA |

| TECYMED |

1 |

EDAR Masia Baló |

| TECYMED |

2 |

EDAR Nova Panorámica Sant Jordi |

| TECYMED |

1 TT-2040 |

EDAR MARINES |

| TECYMED |

2 TP-2020, 1 TT-2035 |

EDAR VALLE DEL ZALABÍ |

| TRAGSA |

1 |

Planta experimental purines |

| TRITIO, S.A. |

1 |

EDAR Urb. Sur Entre Rios |

| TRITIO, S.A. |

1 |

|

| TRITIO, S.A. |

2 TP-2030, 1 TT-2040, 2 TT-2045 |

EDAR DEL CP DE TOPAS (SALAMANCA) Y CP VALLADOLID |

| UNIVERSIDAD COMPLUTENSE MADRID |

1 |

CAMPUS SOMOSAGUAS |

| URBASER |

1 TT-2020 |

AMPLIACION PLANTA DE RESIDUOS MARPOL DRAMAR ANDALUCIA |

| UTE ABASTECIMIENTO PUERTOLLANO |

1 TT-2070 |

EDAR PUERTOLLANO - CIUDAD REAL |

| UTE AMPLIACION ARANJUEZ |

1 |

EDAR Aranjuez |

| UTE AMPLIACION ARANJUEZ |

4 |

EDAR Aranjuez |

| UTE AMPLIACION EDAR LLEIDA |

1 |

AMPLIACIÓN EDAR LLEIDA (BARCELONA) |

| UTE ARROYO DE LA VEGA AMPLIACION EDAR |

1 TP-2570, 1 TP25110 |

EDAR ARROYO DE LA VEGA (MADRID) |

| UTE BERQUEDA CERDANYA |

3 |

EDAR Puigcerdá |

| UTE COLECTORES ARROYO QUIÑONES |

1 TP-2050 |

EBAR ARROYO QUIÑONES |

| UTE COLLOSA-SOCAMEX |

1 |

EDAR ASTORGA (LEON) |

| UTE CONSTRUCTORA PEACHE |

1 |

EDAR MATAPOZUELOS |

| UTE EDAR ABARÁN |

2 |

EDAR Abarán/Murcia |

| UTE EDAR BOADILLA |

3 |

EDAR Boadilla del Monte |

| UTE EDAR'S GUADALAJARA |

1 TT-2040 |

EDAR'S GUADALAJARA |

| UTE EDAR OSUNA |

2 TP-2030 |

EDAR OSUNA |

| UTE EDAR RIO LOBOS |

4 |

Cañón del Río Lobos |

| UTE EDAR RIOJA |

4 |

EDAR S. Asensio, Baños de .... |

| UTE EDAR TALAVERA |

1 |

AMPLIACION EDAR TALAVERA DE LA REINA |

| UTE EDAR TORRELAGUNA |

1 |

EDAR TORRELAGUNA |

| UTE LUMBRALES |

2 TT-2020, 1 TP-2070 |

UTE LUMBRALES |

| UTE MADRIGAL DE LAS AATT |

1 |

EDAR MADRIGAL DE LAS AATT |

| UTE SYD AGUAS XXVIII |

1 |

EDAR SAN ADRIAN |

| UTE UICESA-DHA |

2 |

EDAR CENTRO PENITENCIARIO ALBOCASSER |

| UTE VILLAMA |

4 |

Villamalea/Casas Ibañez |

| UTEDAR |

1 |

EDAR Huesca |

| VELASCO OBRAS Y SERVICIOS |

1 |

EBAR LAS ARROYADAS - S.S. DE LOS REYES |

| ZENITH TOLEDO |

1 TP 2050 |

BOMBEO FECALES |

FILTRAMAS, S.A. has a wide range of solutions for the transport and compacting of the waste extracted by its machines, in a clean and discreet. The conveying and compacting systems can be with screws with final draining zone or hydraulic presses.

The conveyor-compactor screws supplied by FILTRAMAS, S.A., coupled together with its equipment, allow us to obtain a totally clean and fair-faced installation. The screw loading openings are designed for coupling to the discharge opening of the extraction equipment (bars movable grilles or screens), and the intermediate spaces are covered by a fairing.

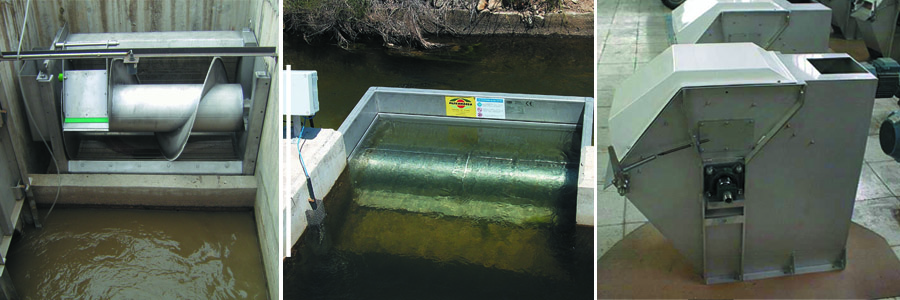

Band screens are those equipments, installed in a channel or , which has a series of filtering surfaces in continuous movement. Its mission is to extract the suspended solids of a certain size that accompany the effluent. There are several types of band screens, depending on the characteristics of the effluent and the installation:

The objective of this equipment is to protect the WWTP or pumping well from the possible arrival of large objects capable of causing obstructions in the different units of the installation. This operation consists of passing the waste water through a screen that separates and evacuates the bulky materials dragged along. They will retain large-sized solids such as branches, leaves, paper, tree roots, plastics, wipes, rags, etc., preventing damage and blockages to pumps, valves, pipes and other elements present in subsequent treatment processes of the purification plant.

These devices allow to continue filtering while performing self-cleaning, being especially suitable for those applications where continuous filtering is an important parameter of the process. Filtramas recommends the installation of its FB or FW in-line filters according to the flow and filtration needs.

Filter sieves offer high performance in the solid-liquid separation process. Our range of equipment responds to the different possible needs for each case.

FILTRAMAS, S.A. has a wide range of solutions for the transport and compacting of the waste extracted by its machines, in a clean and discreet. The conveying and compacting systems can be with screws with final draining zone or hydraulic presses.

The conveyor-compactor screws supplied by FILTRAMAS, S.A., coupled together with its equipment, allow us to obtain a totally clean and fair-faced installation. The screw loading openings are designed for coupling to the discharge opening of the extraction equipment (bars movable grilles or screens), and the intermediate spaces are covered by a fairing.

In any water treatment or purification plant, there is a continuous need to isolate or regulate the flow of water in the channels and manholes or holes in walls (wall gates). This function is carried out by means of the placement of gates and cofferdams.

The result of our experience is the establishment of a standardization that determines a satisfactory result with a simple construction. For this reason, Filtramas has been developing the manufacture of penstocks and flashboards.

Filtramas manufactures channel hatches, wall hatches and cofferdams for different applications and uses.

The accumulation of solid waste in water treatment requires effective mechanized solutions for its extraction. FILTRAMAS, S.A. has a wide variety of equipment for the dragging of solid waste.

In the biological treatment of wastewater, a series of processes are generated based on the cultivation of bacterial microorganisms for the elimination of organic matter, nitrogen and phosphorus. It is one of the most common treatments for its simplicity and low cost.

FILTRAMAS, S.A. has a wide variety of equipment for bacterial culture applied to the treatment of urban and industrial wastewater.

The dewatering of sludge is an essential process in the management of solid waste generated in water treatment. FILTRAMAS, S.A. offers different mechanized solutions to the problem according to the different possible needs.

FILTRAMAS S.A. has a wide variety of solutions for all kinds of problems associated with the treatment and cleaning of water, mud and sand. We develop our specialisation on the basis of the experience accumulated by our professionals, constant effort and close collaboration with our clients. FILTRAMAS S.A. perfects new products, looking for economic and effective solutions. Any problem that arises in the handling of fluids is carefully analyzed in order to find an economically balanced solution.