WASTE COMPACTING CONVEYORS > FP Compactor

INTRODUCTION:

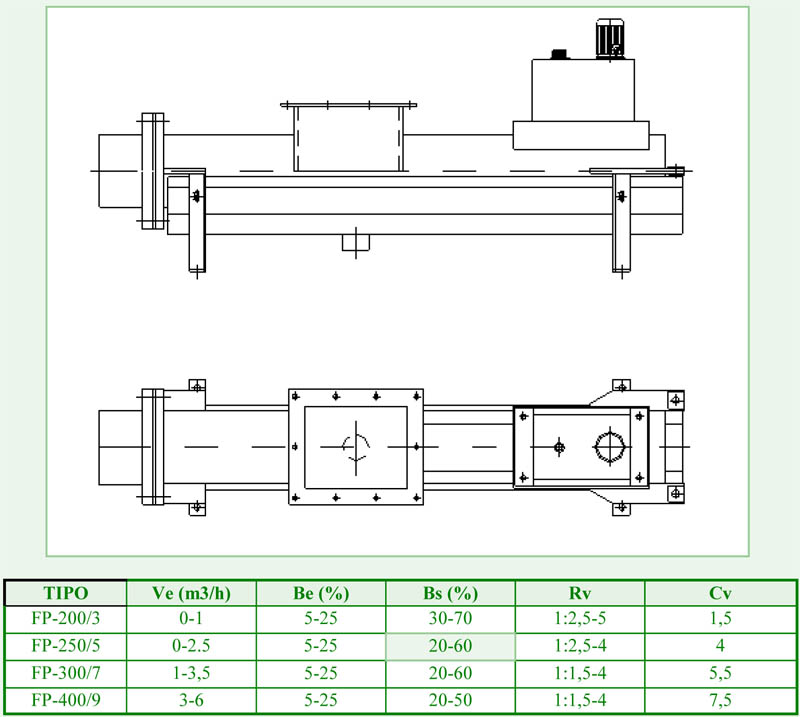

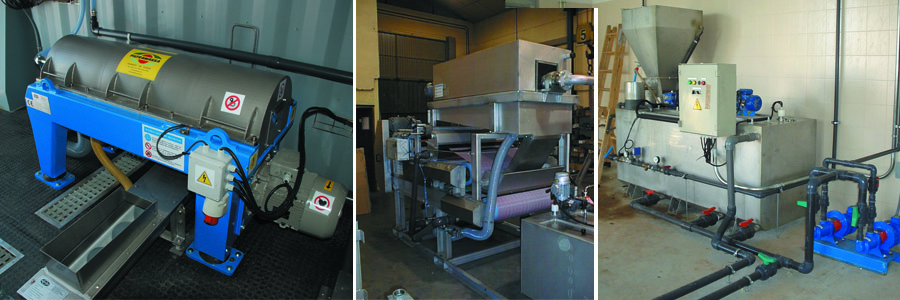

The FP hydraulic presses are particularly suitable for compacting coarse screen waste due to the nature of the solids extracted by the screen and the possibility of screw jamming. The body construction is made of stainless steel. The compacted solids are evacuated through a pipe.

DESCRIPTION:

In all wastewater treatment plants, treatment plants, pumping stations, etc., a grinding process is carried out to generate waste. The amount of waste roughened will depend directly on the clearance of the equipment used for this function and on the dimensions of the transport manifolds.

The dry matter content of roughing residues in urban water is between 10-25%, depending on the sieving process, and the organic content can be up to 90%. Due to the high water content we must treat the waste before its treatment. The best way is to press it down to reduce the moisture content of the residue considerably. This results in less waste to be managed, significantly reducing operating costs.

The FP hydraulic presses are constructed of the following materials:

- Press body: AISI-304 or AISI-316

- Compression chamber: AISI-304 or AISI-316

- Oil hydraulic cylinder: Carbon steel.

-

Draining pan: AISI-304 or AISI-316

The loading hopper and discharge line can be supplied on request. The quality of materials depends on the customer’s needs.

GENERAL DIMENSIONS:

|

CLIENTE / CUSTOMER |

CANT./QTY |

PROYECTO / PROJECT |

| AGUAS FILTRADAS |

2 |

Viveros |

| AQUAGEST MEDIOAMBIENTE |

1 |

SEARSA |

| AQUAGEST MEDIOAMBIENTE |

1 |

EDAR AEROPUERTO DE GERONA |

| ASTEISA |

1 |

Ribadeo |

| BEKOX |

1 |

--- |

| CADAGUA |

2 |

Azpeitia |

| CADAGUA |

1 |

Onteniente |

| CADAGUA |

1 |

EDAR L'Horta Nord |

| CADAGUA |

1 |

EDAR Segovia |

| CADAGUA |

2 |

EDAR Aljarafe |

| CETRANSA |

1 |

--- |

| DEBEOCAN |

1 |

EBAR EL MATORRAL - FUERTEVENTURA |

| DEGREMONT |

2 |

Arroyo del Soto |

| DRAGADOS Y CONT. |

1 |

EDAR Churriana |

| DRAGADOS Y CONT. |

2 |

EDAR Burgos |

| DRAGADOS Y CONT. |

1 |

EDAR Navalcarnero |

| DRAGADOS Y CONT. |

1 |

EDAR Ibiza |

| DRAGADOS Y CONT. |

1 |

EDAR Llanes |

| DRAGADOS Y CONT. |

1 |

Villafranca del Penedes |

| DRAGADOS Y CONT. |

2 |

Elda |

| DYTRAS |

1 |

Isla Cristina |

| DYTRAS |

1 |

Pretratamiento Valle Gran Rey |

| DYTRAS |

1 |

San Esteban de la Gomera |

| ELEUSIS |

1 |

--- |

| ESOHISA |

1 |

--- |

| ESPINA OBRAS HIDRAULICAS |

1 |

CIUDAD DE LA COSTA (URUGUAY) |

| FCC |

1 |

EDAR Figueras |

| FCC |

1 |

EDAR Fuente el Saz |

| GESTAGUA |

1 |

EDAR CULLEREDO (LA CORUÑA) |

| GRUTECONSA |

1 |

Marinaleda |

| HIDROCALOR ANDALUCIA |

2 |

Los Arqueros |

| HIMEXSA |

1 |

El Palmar |

| HOSPITAL COSTA DEL SOL |

1 |

Hospital Costa del Sol |

| INFILCO ESPAÑOLA |

1 |

EDAR Torrente |

| INI MEDIOAMBIENTE |

1 |

EDAR Porreras |

| INITEK |

1 |

EDAR Ea |

| INTAGUA |

1 |

Xeresa |

| LUIS BATALLA |

1 |

Xabia |

| MP MEDIOAMBIENTE |

1 |

SISTEMA COMPACTACION |

| PASSAVANT ESPAÑA S.A. |

1 |

EDAR SMOLIAN (BULGARIA) |

| PRIDESA |

2 |

EDAR Almeria |

| PRIDESA |

1 |

Sant Lluis |

| PRIDESA |

1 |

EDAR Guadalhorce |

| PROSERPOL |

1 |

EDAR Algemesi |

| SAICO |

1 |

Tavernes |

| SITRA |

1 |

EDAR LES CARRASES, LLIRIA |

| SOGEA |

2 |

Frielas |

| SPA |

1 |

Aeropuerto Lanzarote |

| SULZER |

1 |

San Carlos de la Rapita |

| SYV SACYR VALLEHERMOSO |

1 |

EDAR LA REGUERA |

| TAESA |

1 |

|

| TALL. AVELINO ESGUEVA |

1 |

--- |

| TECNICAS REUNIDAS |

1 |

Guadalhorce |

| TECYMED |

2 |

EDAR Masia Baló |

| TRITIO |

1 |

Burriana |

| TRITIO |

1 |

--- |

| UTE EXPLOTACIONES REJAS VALDEBEBAS |

1 |

EDAR VALDEBEBAS |

| UTE PRIDESA-CUBIERTAS |

1 |

Edar León |

| UTEDAR |

1 |

Huesca |

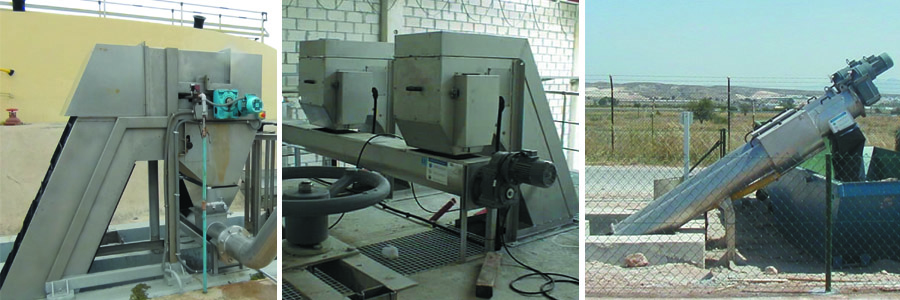

FILTRAMAS, S.A. has a wide range of solutions for the transport and compacting of the waste extracted by its machines, in a clean and discreet. The conveying and compacting systems can be with screws with final draining zone or hydraulic presses.

The conveyor-compactor screws supplied by FILTRAMAS, S.A., coupled together with its equipment, allow us to obtain a totally clean and fair-faced installation. The screw loading openings are designed for coupling to the discharge opening of the extraction equipment (bars movable grilles or screens), and the intermediate spaces are covered by a fairing.

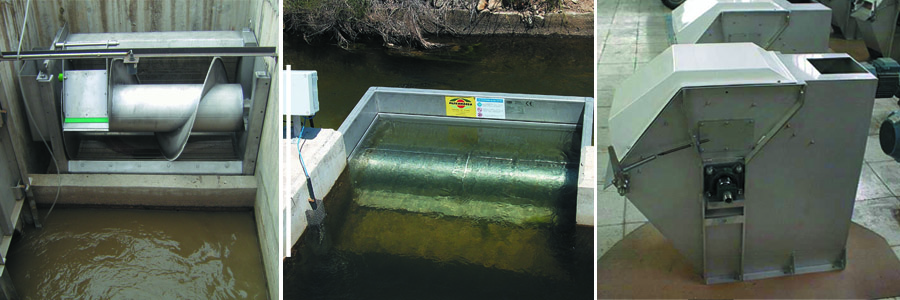

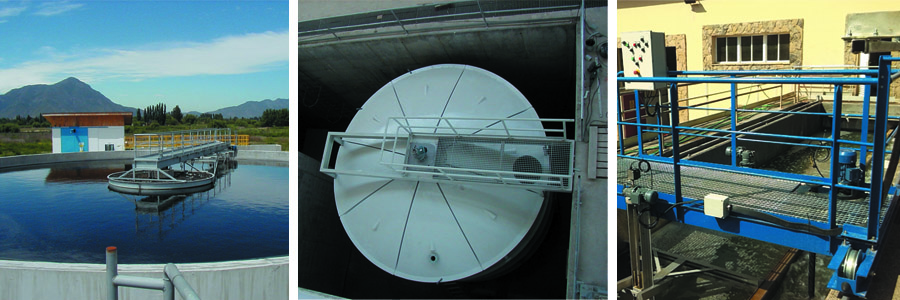

Band screens are those equipments, installed in a channel or , which has a series of filtering surfaces in continuous movement. Its mission is to extract the suspended solids of a certain size that accompany the effluent. There are several types of band screens, depending on the characteristics of the effluent and the installation:

The objective of this equipment is to protect the WWTP or pumping well from the possible arrival of large objects capable of causing obstructions in the different units of the installation. This operation consists of passing the waste water through a screen that separates and evacuates the bulky materials dragged along. They will retain large-sized solids such as branches, leaves, paper, tree roots, plastics, wipes, rags, etc., preventing damage and blockages to pumps, valves, pipes and other elements present in subsequent treatment processes of the purification plant.

These devices allow to continue filtering while performing self-cleaning, being especially suitable for those applications where continuous filtering is an important parameter of the process. Filtramas recommends the installation of its FB or FW in-line filters according to the flow and filtration needs.

Filter sieves offer high performance in the solid-liquid separation process. Our range of equipment responds to the different possible needs for each case.

FILTRAMAS, S.A. has a wide range of solutions for the transport and compacting of the waste extracted by its machines, in a clean and discreet. The conveying and compacting systems can be with screws with final draining zone or hydraulic presses.

The conveyor-compactor screws supplied by FILTRAMAS, S.A., coupled together with its equipment, allow us to obtain a totally clean and fair-faced installation. The screw loading openings are designed for coupling to the discharge opening of the extraction equipment (bars movable grilles or screens), and the intermediate spaces are covered by a fairing.

In any water treatment or purification plant, there is a continuous need to isolate or regulate the flow of water in the channels and manholes or holes in walls (wall gates). This function is carried out by means of the placement of gates and cofferdams.

The result of our experience is the establishment of a standardization that determines a satisfactory result with a simple construction. For this reason, Filtramas has been developing the manufacture of penstocks and flashboards.

Filtramas manufactures channel hatches, wall hatches and cofferdams for different applications and uses.

The accumulation of solid waste in water treatment requires effective mechanized solutions for its extraction. FILTRAMAS, S.A. has a wide variety of equipment for the dragging of solid waste.

In the biological treatment of wastewater, a series of processes are generated based on the cultivation of bacterial microorganisms for the elimination of organic matter, nitrogen and phosphorus. It is one of the most common treatments for its simplicity and low cost.

FILTRAMAS, S.A. has a wide variety of equipment for bacterial culture applied to the treatment of urban and industrial wastewater.

The dewatering of sludge is an essential process in the management of solid waste generated in water treatment. FILTRAMAS, S.A. offers different mechanized solutions to the problem according to the different possible needs.

FILTRAMAS S.A. has a wide variety of solutions for all kinds of problems associated with the treatment and cleaning of water, mud and sand. We develop our specialisation on the basis of the experience accumulated by our professionals, constant effort and close collaboration with our clients. FILTRAMAS S.A. perfects new products, looking for economic and effective solutions. Any problem that arises in the handling of fluids is carefully analyzed in order to find an economically balanced solution.