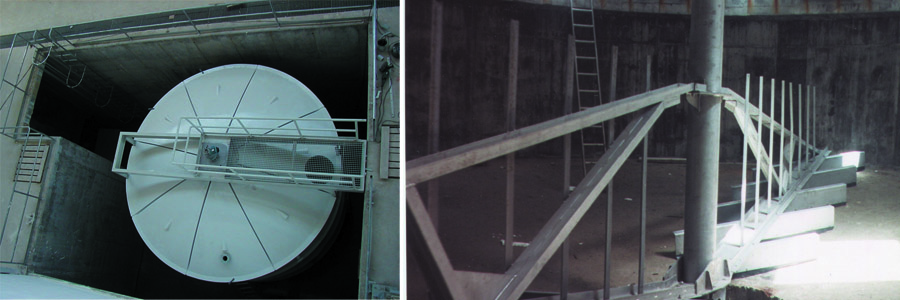

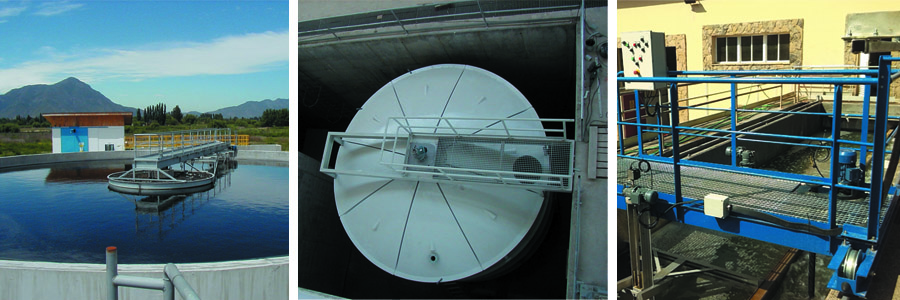

SOLIDS DRAG MECHANISMS > Central Traction Thickener

INTRODUCTION:

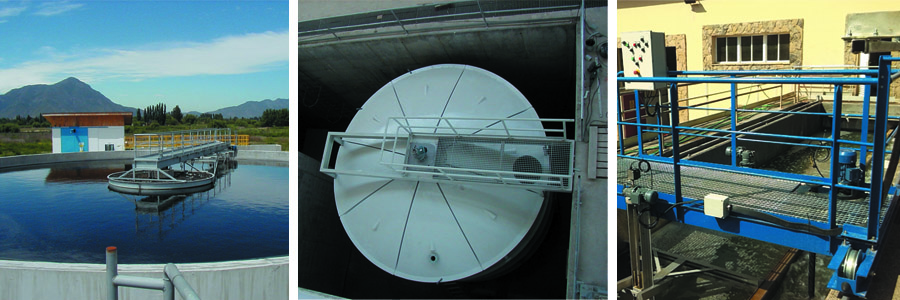

FILTRAMAS, S.A. designs and installs central traction thickeners for sludge concentrate, used in various applications. The design of this equipment is particularly robust.

FILTRAMAS,S.A. presents control heads for thickeners, equipped with manual or automatic scraper lifting systems by means of an electric servomotor controlled by a high torque signal.

FILTRAMAS, S.A. also manufactures TROMMEL sludge thickeners (pre-dewaterers), which allow the concentration of sludge to increase dramatically, as a preliminary step to the dehydration process.

DESCRIPTION:

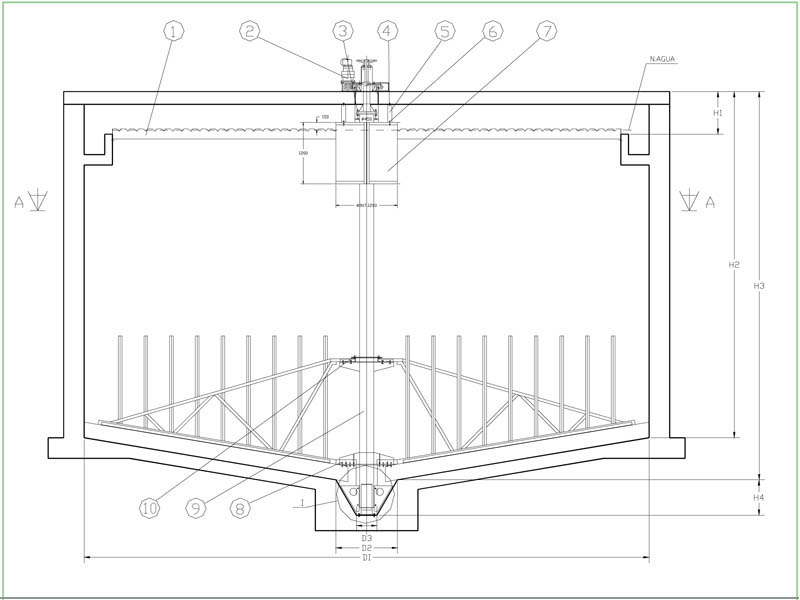

FILTRAMAS, S.A. designs and installs central traction thickeners for sludge concentrate in various applications. The design of this equipment is particularly robust. They have a control head and are equipped with manual or automatic scraper lifting systems using an electric actuator. The central traction thickener mechanism consists of the following elements:

-

Drive unit: An auxiliary scraper lifting system can be installed for both the control head drive and the gearmotor drive.

-

Support column: Constructed in tube or latticework.

-

Thickening structures: Forming a latticework, they have thickening spikes in an angle profile and support the scrapers, which are bolted to the main beam.

-

Sweeping scrapers: Made of folded sheet metal, finished with a neoprene friction band. They form a herringbone trawl assembly.

-

Feeding cylinder: It is built in two halves in sheet metal, reinforcements and angled profiles. It is fixed to the support column assembly. Its mission is to stabilize the incoming sludge flow.

-

Perimeter spillway: It is usually built in aluminium. It is fixed to the concrete perimeter channel by means of fixing clamps to facilitate the levelling of the landfill. The staples are anchored to the concrete by means of anchor bolts. Optionally, thickeners can be supplied with float dragging system.

-

Protection cover: FILTRAMAS can design, supply and mount the thickener cover in GRP with gel coat finish.

-

Standard manufacturing materials: ST-52 carbon steel, with hot dip galvanized or double galvanized + painted treatment. Also available in stainless steel AISI-304 or AISI-316, depending on the customer’s needs.

GENERAL DIMENSIONS:

|

CLIENTE / CUSTOMER |

CANT./QTY |

PROYECTO / PROJECT |

| ABENSUR |

1 |

EDAR Los Villares |

| ABENSUR |

1 |

EDAR Aljarafesa |

| ACCIONA AGUA |

1 |

EDAR EL QUIÑON |

| ACCIONA AGUA |

2 |

EDAR VILLAROBLEDO |

| ACCIONA AGUA |

1 |

ETA PINHAO-VILA REAL-TRAS-OS MONTES (PORTUGAL) |

| ACT SISTEMAS S.L. |

1 |

ABASTECIMIENTO EL CONDADO |

| AGUAS FILTRADAS |

2 |

Depuradora Casino |

| ALCEDAR |

1 |

Alcorisa |

| AMBIENTALIA LEVANTE SL |

1 |

EDARI POSTRE REINA/CARAVACA/MURCIA |

| AQUAGEST |

1 |

ETAP AMPLIACION ATALAYA |

| ASTEISA |

1 |

Vila de Cruces |

| ASTEISA |

1 |

Verin |

| ASTEISA |

1 |

Pontenova |

| ASTEISA |

1 |

Arnoia |

| ASTEISA |

1 |

Veigue |

| ASTEISA |

1 |

Bretoña, Edar Pastoriza |

| ASTEISA |

1 |

EDAR Badaran (La Rioja) |

| ASTEISA |

1 |

EDAR Taboada (Lugo) |

| COMYLSA |

1 |

EDAR Sagunto |

| CONST. Y CONTRATAS |

1 |

EDAR rejas |

| CONSTRUCCIONES SARRION |

4 |

EDAR'S Calatrava |

| CONSTRUCCIONES SARRION |

1 |

EDAR LA SAGRA |

| CONTRATAS LA MANCHA |

2 |

Depuradora Terrinches, Albadalejo y otras |

| CUBIERTAS |

1 |

Guadix |

| CUBIERTAS |

1 |

C.P. Topas |

| CUBIERTAS |

1 |

EDAR Golf (Málaga). |

| CUBIERTAS |

1 |

Zuera |

| CUBIERTAS |

1 |

C.P. Huelva |

| CUBIERTAS |

1 |

EDAR Sanxenxo |

| CUBIERTAS |

1 |

C.P. Alama |

| DEIDA |

2 |

Varios |

| DEGREMONT |

1 |

CORMEI |

| DEMAIN |

1 |

EDAR ESTEIRO-MUROS |

| DEPUMASTER |

1 |

Ubrique |

| DHVEM |

1 |

ETAR de Minde e Mira d’Aire |

| DINOTEC |

1 |

EDAR Santa Bárbara (Murcia) |

| DINOTEC |

1 |

EDAR Benallup |

| DINOTEC |

1 |

EDAR Estepa |

| DINOTEC |

1 |

Palma de Mallorca |

| DINOTEC |

1 |

ETAP LORCA |

| DINOTEC |

1 |

EDAR Valle del Gran Rey |

| DINOTEC |

1 |

EDAR Torredelcampo |

| DINOTEC |

1 |

EDAR LAS PAJANOSAS |

| DINOTEC |

1 |

EDAR SAN MATEO (LAS PALMA DE GRAN CANARIA) |

| DINOTEC |

1 |

EBAR SAN GEOLIT Y AMP. EDAR MENGIBAR |

| DRACE |

1 |

ETAP Torrijos |

| DRACE |

1 |

EDAR ROBLEDILLO |

| DRACE |

1 |

EDAR BERZOSA |

| DRAGADOS |

1 |

CP ESTREMERA/MADRID |

| DYTRAS |

1 |

Celanova |

| DYTRAS |

1 |

Fonsagrada |

| DYTRAS |

1 |

--- |

| DYTRAS |

1 |

EDAR Axarquia |

| DYTRAS |

1 |

EDAR Jabugo |

| DYTRAS |

1 |

EDAR Alcalá del Valle |

| DYTRAS |

1 |

EDAR BELMEZ (CORDOBA) |

| DYTRAS |

1 |

EDAR BELALCAZAR |

| DYTRAS |

1 |

MINAS DE RIOTINTO ETAP |

| DYTRAS |

1 |

EDAR ALAMEDA (MALAGA) |

| ECOPRENEUR CHILE |

1 |

COIHUECO, YUMBEL |

| ECOPRENEUR CHILE |

1 |

AGROSUPER |

| ECOPRENEUR CHILE |

1 |

Planta Riles de la Estrella |

| ECOPRENEUR CHILE |

1 |

Proyecto Aguas Santiago |

| ECOTÉCNICA |

1 |

EDAR Golega |

| EDAR ALMAZAN UTE |

1 |

EDAR Almazán / Soria |

| EDAR BAEZA UTE(AQUALIA-EMSA) |

1 |

EDAR BAEZA (JAEN) |

| EDAR SAHAGUN UTE |

1 |

EDAR SAHAGUN |

| EMAYA |

2 |

EDAR Mallorca II |

| EMPRESA MUNICIPAL CUENCA |

1 |

GUAYAQUIL-ECUADOR |

| EPTISA |

1 |

EDAR CUIÑA |

| ESPINA OBRAS HIDRAULICAS |

1 |

Cospeito-Muimenta |

| ESPINA OBRAS HIDRAULICAS |

1 |

EDAR Baltanas |

| ESPINA OBRAS HIDRAULICAS |

1 |

EDAR PEÑAFIEL (VALLADOLID) |

| ESPINA OBRAS HIDRAULICAS |

1 |

SUPLEMENTO EDAR PEÑAFIEL |

| FBO CONSULTORES |

1 |

Coimbra |

| FCC |

1 |

C.P. Albolote |

| FCC-SPA U.T.E |

1 |

EDAR Boadilla |

| FERROVIAL |

1 |

Yecla |

| FERROVIAL-AGROMAN |

2 |

EDAR Alcantarilla |

| GRUTECONSA |

1 |

ETAP Santillana |

| IMFLUID S.L. |

1 |

EDAR Algarrobo |

| IMFLUID S.L. |

1 |

EDAR POL. JUNCARIL-ASEGRA ALBOLOTE (GRANADA) |

| IMOSA |

1 |

Nules |

| INFILCO |

1 |

Xátiva |

| INFILCO |

2 |

Montcada |

| INFILCO |

2 |

Peñón del Cuervo |

| INFILCO |

1 |

Alcudia |

| INFILCO |

1 |

Cariñena |

| INFILCO |

1 |

EDAR Sueca |

| INFILCO |

2 |

EDAR Bejar |

| INI MEDIOAMBIENTE |

1 |

EDAR Porreras |

| INIMEDIOAMBIENTE |

1 |

Jealsa |

| INITEK |

1 |

EDAR ARANA (ALAVA) |

| ISOLUX WAT |

1 |

C.P. Dueñas |

| ISOLUX WAT |

1 |

Opel |

| ISOLUX WAT |

1 |

Viella |

| ISOLUX WAT |

1 |

EDAR Villaconejos |

| ISOLUX WAT |

1 |

EDAR Fuente el Saz |

| ISOLUX WAT |

1 |

EDAR Calasparra |

| ISOLUX WAT |

1 |

EDAR Herencia |

| M.JOCA |

1 |

EDAR Valdelacalzada |

| MP SERVICIOS INDUSTRIALES |

1 |

EDAR DE EL CUERVO |

| NECSO |

1 |

C.P. Aranjuez |

| OCP |

2 |

EDAR Denia |

| OCP |

1 |

Cabañas Pontedeume |

| OHL |

1 |

TUNER AVE |

| OTV |

2 |

EDAR Ibiza |

| PASSAVANT ESPAÑA S.A. |

1 |

PORTO DO SON |

| PASSAVANT-COPASA |

1 |

EMISARIO Y EDAR VILLABRAZARO (ZAMORA) |

| PASSAVANT-COPASA |

1 |

EMISARIO Y EDAR BOÑAR (LEÓN) |

| PERSOND |

1 |

EDAR Bolonia (Tarifa-Cadiz) |

| PRIDESA |

1 |

Es-Mitjorn |

| PRIDESA |

1 |

EDAR Puente Genil |

| PRIDESA |

1 |

EDAR Cehegín |

| PRIDESA |

2 |

EDAR Tanger |

| PROSEIN |

1 |

EDAR El Trocadero |

| REYMAUX |

1 |

EDAR Oropesa |

| RIEGOSUR |

1 |

EDAR Carmona |

| SOCAMEX |

1 |

Emisario y EDAR Tudela de Duero |

| SOCAMEX |

1 |

EDAR Iscar |

| SOCAMEX |

1 |

EDAR Soller |

| SOCAMEX |

1 |

EDAR BARRUELO (PALENCIA) |

| SOGEA |

2 |

Frielas |

| SOGEA |

2 |

Freixo |

| SPA |

1 |

Benquerencia. |

| SPA |

2 |

Toledo |

| SPA |

1 |

EDAR La Sagra |

| SPA |

1 |

EDAR EL Espinar |

| SPA |

1 |

EDAR Urb. Señorio de Illescas |

| TECNICAS REUNIDAS |

2 |

Aceria Wuhan (China). |

| TECVASA |

1 |

EDAR LORIGUILLA |

| TECYMED |

1 |

EDAR Masia Bach Sant Esteve Sesrovires |

| TECYMED |

1 |

P.I. La Foya de Quartell |

| TECYMED |

1 |

EDAR Masia Baló |

| TRITIO |

1 |

EDAR CP TOPAS |

| UTE AFINO |

24 |

ETAP Santillana |

| UTE AMPLIACION ARANJUEZ |

1 |

EDAR Aranjuez |

| UTE COLLOSA-SOCAMEX |

1 |

EDAR ASTORGA (LEON) |

| UTE COMYLSA-DHA |

1 |

EDAR Xixona |

| UTE CORONIL |

1 |

EDAR El Coronil |

| UTE DINOTEC-PRINUR |

2 |

EDAR LOS PEDROCHES |

| UTE ECISA SOCAMEX |

1 |

EDAR Carrizales |

| UTE EDAR'S GUADALAJARA |

1 |

EDAR JADRAQUE |

| UTE EDAR OSUNA |

1 |

EDAR OSUNA |

| UTE EDAR SAN BARTOLOME |

1 |

EDAR SAN BARTOLOME DE LA TORRE (HUELVA) |

| UTE EDAR VALLE DEL SIL |

1 |

Valle del Sil Emisario y EDAR |

| UTE EL PLANTIO |

1 |

Arroyo del Plantio |

| UTE ESTELLA |

2 |

EDAR Estella |

| UTE LUMBRALES |

1 |

UTE LUMBRALES |

| UTE PRIDESA-GRAMAN |

1 |

EDAR Borja |

| UTE SAN ESTEBAN DE GORMAZ |

1 |

EDAR San Esteban de Gormaz |

| UTE TECNICAS REUNIDAS |

1 |

TRATAMIENTO AGUAS PUERTOLLANO |

| UTE TORREPEROJIL |

1 |

EDAR Torreperogil |

| UTE UICESA DHA |

1 |

Centro Penitenciario Albocasser |

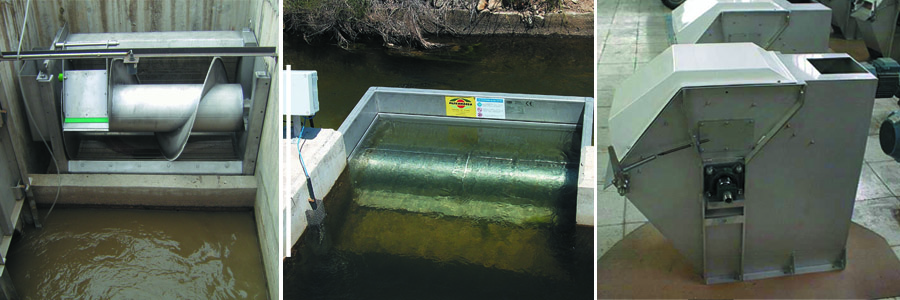

The accumulation of solid waste in water treatment requires effective mechanized solutions for its extraction. FILTRAMAS, S.A. has a wide variety of equipment for the dragging of solid waste.

Band screens are those equipments, installed in a channel or , which has a series of filtering surfaces in continuous movement. Its mission is to extract the suspended solids of a certain size that accompany the effluent. There are several types of band screens, depending on the characteristics of the effluent and the installation:

The objective of this equipment is to protect the WWTP or pumping well from the possible arrival of large objects capable of causing obstructions in the different units of the installation. This operation consists of passing the waste water through a screen that separates and evacuates the bulky materials dragged along. They will retain large-sized solids such as branches, leaves, paper, tree roots, plastics, wipes, rags, etc., preventing damage and blockages to pumps, valves, pipes and other elements present in subsequent treatment processes of the purification plant.

These devices allow to continue filtering while performing self-cleaning, being especially suitable for those applications where continuous filtering is an important parameter of the process. Filtramas recommends the installation of its FB or FW in-line filters according to the flow and filtration needs.

Filter sieves offer high performance in the solid-liquid separation process. Our range of equipment responds to the different possible needs for each case.

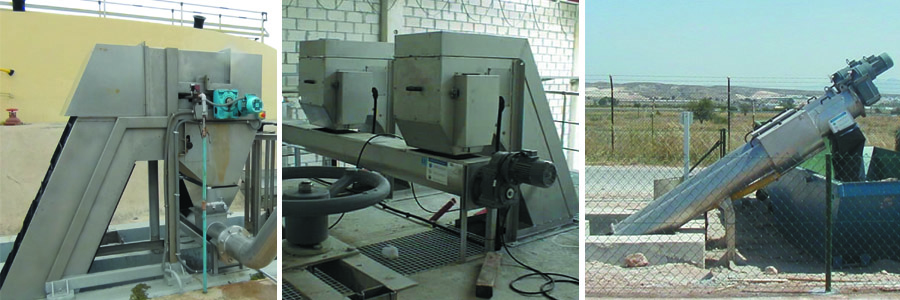

FILTRAMAS, S.A. has a wide range of solutions for the transport and compacting of the waste extracted by its machines, in a clean and discreet. The conveying and compacting systems can be with screws with final draining zone or hydraulic presses.

The conveyor-compactor screws supplied by FILTRAMAS, S.A., coupled together with its equipment, allow us to obtain a totally clean and fair-faced installation. The screw loading openings are designed for coupling to the discharge opening of the extraction equipment (bars movable grilles or screens), and the intermediate spaces are covered by a fairing.

In any water treatment or purification plant, there is a continuous need to isolate or regulate the flow of water in the channels and manholes or holes in walls (wall gates). This function is carried out by means of the placement of gates and cofferdams.

The result of our experience is the establishment of a standardization that determines a satisfactory result with a simple construction. For this reason, Filtramas has been developing the manufacture of penstocks and flashboards.

Filtramas manufactures channel hatches, wall hatches and cofferdams for different applications and uses.

The accumulation of solid waste in water treatment requires effective mechanized solutions for its extraction. FILTRAMAS, S.A. has a wide variety of equipment for the dragging of solid waste.

In the biological treatment of wastewater, a series of processes are generated based on the cultivation of bacterial microorganisms for the elimination of organic matter, nitrogen and phosphorus. It is one of the most common treatments for its simplicity and low cost.

FILTRAMAS, S.A. has a wide variety of equipment for bacterial culture applied to the treatment of urban and industrial wastewater.

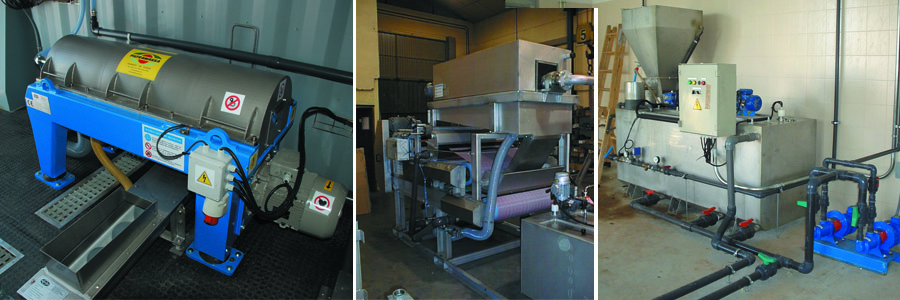

The dewatering of sludge is an essential process in the management of solid waste generated in water treatment. FILTRAMAS, S.A. offers different mechanized solutions to the problem according to the different possible needs.

FILTRAMAS S.A. has a wide variety of solutions for all kinds of problems associated with the treatment and cleaning of water, mud and sand. We develop our specialisation on the basis of the experience accumulated by our professionals, constant effort and close collaboration with our clients. FILTRAMAS S.A. perfects new products, looking for economic and effective solutions. Any problem that arises in the handling of fluids is carefully analyzed in order to find an economically balanced solution.