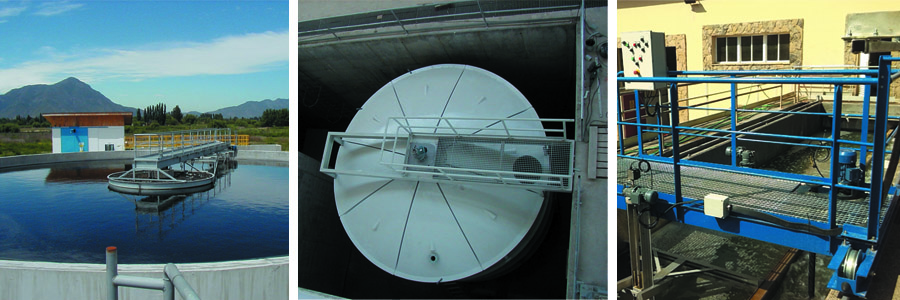

BIOLOGICAL TREATMENT > Rotary distributors SC, DC and M

INTRODUCTION:

FILTRAMAS, S.A. supplies rotary distributors designed to meet the customer’s needs. The design takes into account the available data regarding diameter, maximum flow rate and minimum flow rate. If the customer so desires, our technical service will advise him on the available options and which is the configuration and intensity of flow that better adapt to his needs.

There are single chamber models with splitter arms, double or triple chamber for strong flow rate variations, and motorized with the possibility of speed control. They are manufactured in stainless steel and protected carbon steel.

Bacterial beds or trickling filters are among the oldest biological wastewater treatment systems. It is an aerobic biological purification system whose operation is based on circulating air and wastewater through a porous medium. They are configured in the form of a fixed non-submerged crop and are composed of a bed, usually of large diameter, which may be made up of natural materials – boulders, metallurgical coke, slag or anthracite – or plastics, and on whose surface the waste water is uniformly applied by means of distributors, in the form of rain. At the bottom of the bed are the drainage system for the effluent discharge from the process and the air intake system for ventilation.

DESCRIPTION:

FILTRAMAS rotary distributors are designed to distribute water evenly over the surface of the bacterial bed. For this purpose, the distributor arms have a series of holes located in the centres of gravity of a series of rings which distribute the wastewater proportionally over the surface of the bacterial bed, the jets being opened by means of deflectors.

Depending on the characteristics of the installation, the rotary distributors will comply with the following nomenclature:

-

Model SC: Single chamber rotary distributors. They have 2 delivery arms. They can be installed as long as the flow rate is constant, or at least does not vary by more than 50% over a nominal flow rate.

-

DC Model: Double chamber rotary distributors. They have 4 delivery arms. Two arms are impellers and the remaining two arms are connected to an overflow chamber. They are used as long as the maximum/minimum flow ratio is variable and does not exceed 5:1.

-

DCM model: The M series distributors are equipped with a centrally driven geared motor, which guarantees a controlled speed of rotation. This allows the regulation of the flow intensity, and greater control over the process.

FILTRAMAS rotary distributors have the following FEATURES:

- Maximum inlet flow rate Qmax

- Minimum inlet flow Qmin

-

Bacterial bed diameter

These are the materials used for its manufacture:

- Galvanized carbon steel

- Stainless steel AISI 304

-

Stainless steel AISI 316

|

CLIENTE |

CANT. |

PROYECTO |

| ACUAESTUDIOS |

1 |

EDAR Trujillo |

| ALCER |

1 |

EDAR Barasoain |

| ASPIROZ Y SARALEGUI |

1 |

Ibero |

| CIDA-HIDROQUIMICA |

1 |

Esteve Quimica |

| CIDA-HIDROQUIMICA |

1 |

--- |

| CIDA-HIDROQUIMICA |

1 |

EDAR San Celoni |

| COANSA |

1 |

EDAR Almazán |

| CONSTRUNAVAR |

1 |

EDAR Eugui |

| CONSTRUNAVAR |

1 |

EDAR Urroz |

| CONT. ORTIZ |

8 |

Cervera/Berrueco |

| DINOTEC |

1 |

EDAR EN COBI |

| DYTRAS |

11 |

EDAR Valle del Jerte |

| DYTRAS |

1 |

Olvera |

| DYTRAS |

1 |

Montecorte |

| DYTRAS |

2 |

Olvera |

| ECOPRENEUR CHILE |

2 |

AGROSUPER |

| ELECNOR |

1 |

Planta Experimental |

| FOCSA |

2 |

EDAR Tomelloso |

| FOCSA |

1 |

--- |

| GHESA |

1 |

EDAR S.Martin del Pimpollar |

| GHESA |

2 |

EDAR Villafranca |

| HUARTE |

1 |

EDAR Elizondo |

| INI MEDIOAMBIENTE |

1 |

Cazalla de la Sierra |

| INIMEDIOAMBIENTE |

1 |

Alanis |

| INITEK |

1 |

EDAR ARANA (ALAVA) |

| INTAGUA |

2 |

San Pablo de los Montes |

| MERIDIONAL DE AGUAS |

2 |

Puerto Serrano |

| MP MEDIOAMBIENTE |

1 |

EDAR DE GRAÑON |

| OBENASA |

1 |

Ochagavia |

| OBENASA |

1 |

Sesma |

| OMS IBERICA |

1 |

Planta Piloto Valencia |

| PASTOR Y CANALS |

1 |

--- |

| PRIDESA |

1 |

Tarancón |

| PRIDESA |

3 |

Campezu,Izarra y Mauztu |

| REYMAUX |

1 |

Algodonales |

| SMYTA |

1 |

EDAR Alcazar de S. Juan |

| SOCAMEX |

1 |

Constantina. |

| SPA |

1 |

Toledo |

| TRITIO |

1 |

--- |

| URB.CONSTR. DE TALAVERA |

2 |

Talavera |

| UTE DINOTEC CASLESA |

1 |

EDAR VILLANUBLA |

| UTE ESTELLA |

3 |

EDAR Estella |

| WAT |

1 |

EDAR Sonseca |

In the biological treatment of wastewater, a series of processes are generated based on the cultivation of bacterial microorganisms for the elimination of organic matter, nitrogen and phosphorus. It is one of the most common treatments for its simplicity and low cost.

FILTRAMAS, S.A. has a wide variety of equipment for bacterial culture applied to the treatment of urban and industrial wastewater.

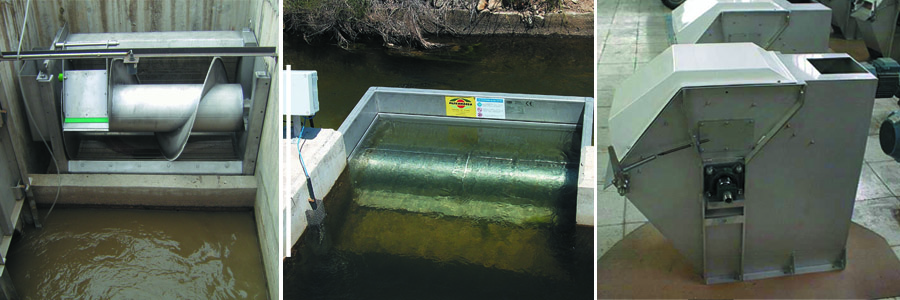

Band screens are those equipments, installed in a channel or , which has a series of filtering surfaces in continuous movement. Its mission is to extract the suspended solids of a certain size that accompany the effluent. There are several types of band screens, depending on the characteristics of the effluent and the installation:

The objective of this equipment is to protect the WWTP or pumping well from the possible arrival of large objects capable of causing obstructions in the different units of the installation. This operation consists of passing the waste water through a screen that separates and evacuates the bulky materials dragged along. They will retain large-sized solids such as branches, leaves, paper, tree roots, plastics, wipes, rags, etc., preventing damage and blockages to pumps, valves, pipes and other elements present in subsequent treatment processes of the purification plant.

These devices allow to continue filtering while performing self-cleaning, being especially suitable for those applications where continuous filtering is an important parameter of the process. Filtramas recommends the installation of its FB or FW in-line filters according to the flow and filtration needs.

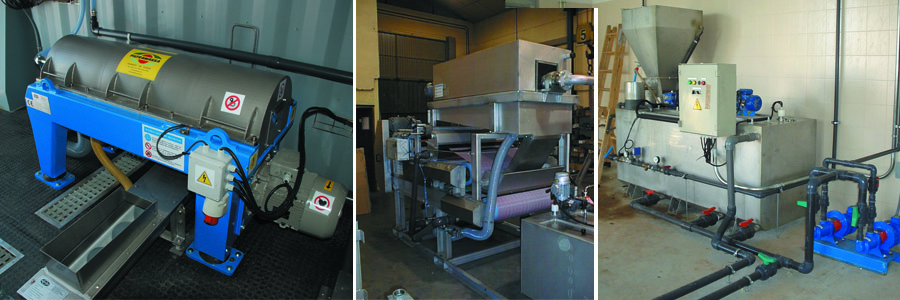

Filter sieves offer high performance in the solid-liquid separation process. Our range of equipment responds to the different possible needs for each case.

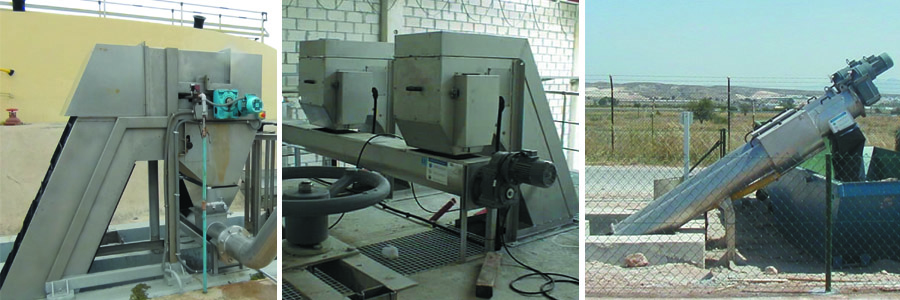

FILTRAMAS, S.A. has a wide range of solutions for the transport and compacting of the waste extracted by its machines, in a clean and discreet. The conveying and compacting systems can be with screws with final draining zone or hydraulic presses.

The conveyor-compactor screws supplied by FILTRAMAS, S.A., coupled together with its equipment, allow us to obtain a totally clean and fair-faced installation. The screw loading openings are designed for coupling to the discharge opening of the extraction equipment (bars movable grilles or screens), and the intermediate spaces are covered by a fairing.

In any water treatment or purification plant, there is a continuous need to isolate or regulate the flow of water in the channels and manholes or holes in walls (wall gates). This function is carried out by means of the placement of gates and cofferdams.

The result of our experience is the establishment of a standardization that determines a satisfactory result with a simple construction. For this reason, Filtramas has been developing the manufacture of penstocks and flashboards.

Filtramas manufactures channel hatches, wall hatches and cofferdams for different applications and uses.

The accumulation of solid waste in water treatment requires effective mechanized solutions for its extraction. FILTRAMAS, S.A. has a wide variety of equipment for the dragging of solid waste.

In the biological treatment of wastewater, a series of processes are generated based on the cultivation of bacterial microorganisms for the elimination of organic matter, nitrogen and phosphorus. It is one of the most common treatments for its simplicity and low cost.

FILTRAMAS, S.A. has a wide variety of equipment for bacterial culture applied to the treatment of urban and industrial wastewater.

The dewatering of sludge is an essential process in the management of solid waste generated in water treatment. FILTRAMAS, S.A. offers different mechanized solutions to the problem according to the different possible needs.

FILTRAMAS S.A. has a wide variety of solutions for all kinds of problems associated with the treatment and cleaning of water, mud and sand. We develop our specialisation on the basis of the experience accumulated by our professionals, constant effort and close collaboration with our clients. FILTRAMAS S.A. perfects new products, looking for economic and effective solutions. Any problem that arises in the handling of fluids is carefully analyzed in order to find an economically balanced solution.