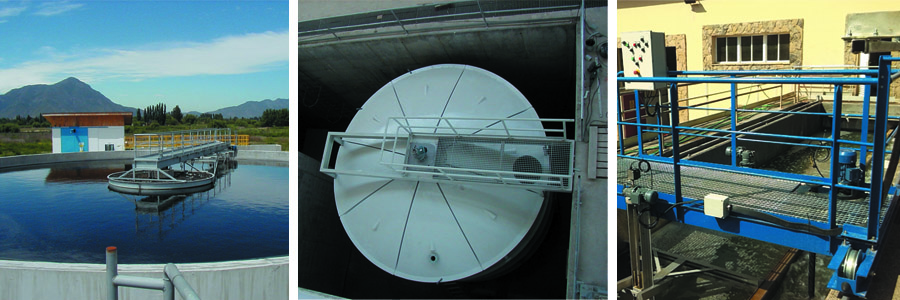

SOLIDS DRAG MECHANISMS > Sand trap Bridge

INTRODUCTION:

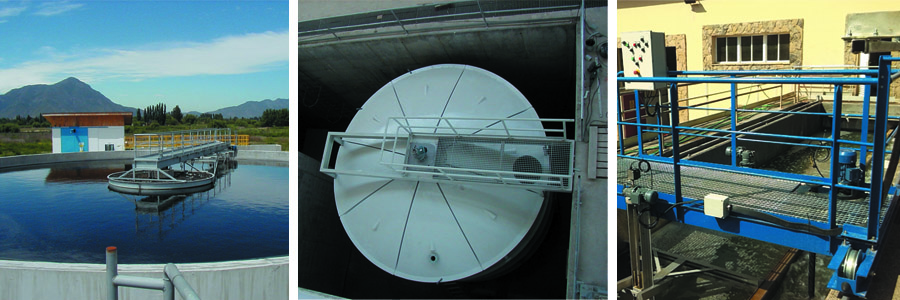

The scraper bridges for rectangular sand collectors manufactured by FILTRAMAS, S.A. have been designed to extract sand and grease effectively.

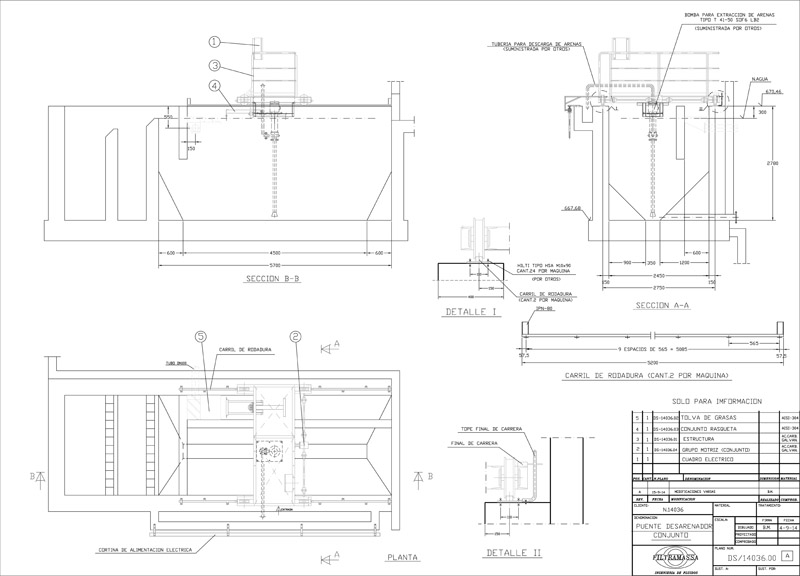

The mechanism consists on a bridge that can be moved longitudinally to allow the sweeping scrapers to move vertically. The bridge is moved by means of double flange wheels that roll on rails located at the ends of the sweeping bridge.

Normally, this process is aerated by blower units that help to ensure the correct demulsified of the grease. Substances with a specific weight lower than water float forming a surface layer. In this way the grease is retained and removed by the squeegee. The sands that are deposited on the bottom are extracted by a pump for further treatment in a sand classifier; the fats and floats are sent to a fat concentrator and the water is returned to the primary decanter.

DESCRIPTION:

The sweeping bridge for the sand collector channel consists of the following elements:

-

Structure: The structure of the mechanism is a platform on the tanks mounted on two driving carriages located on the outer walls. The structure is made up of commercial profiles reinforced with cross braces. The carriages are constructed of profiles mounted under the main bridge. Access is provided at one end of the platform. The platform surface has been designed with removable galvanized TRAMEX-type flooring, to allow free access to the different lubrication points, anchored to the profiles that form the bridge.

-

Suspension: The machine is supported on the outer walls by double flanged wheels mounted on bearings. These bearings shall be mounted on racks of trolleys. The double flange wheels must be designed in such a way that the machine is centred on the rail to absorb temperature-related contractions.

-

Diving Gearmotor Group: The translation movement is established by means of a drive unit made up of a gearmotor. On the output shaft of the gear unit, the transmission rods are mounted on bearings and connected by means of detachable couplings. At the ends of these bars the drive wheels are stuck.

-

The scraper lifting/lowering unit: The movement of the scrapers is carried out by means of a motor reducer of suitable power that drives the lifting and lowering of the scraper by means of a spindle and threaded nut.

-

Electrical transmission system: The transmission is usually carried out by means of a power supply curtain.

-

Sliding rails: The rails shall be of the trolley type. Anchors are provided at regular intervals for fixing to O.C. using anchor bolts and fixing clamps.

-

Sweeping scrapers: Sweeping scrapers shall be made up of profiles and commercial plates which are suitably joined together. These parts shall be subjected to an anti-corrosion treatment. The scrapers will be finished off with 10 mm thick neoprene strips protruding approximately 50 mm from the metal parts.

GENERAL DIMENSIONS :

|

CLIENTE |

CANT. |

PROYECTO |

| ABENSUR |

1 |

EDAR Los Villares/Jaén |

| ABENSUR |

2 |

EDAR El Vellón, El Molar ... |

| ABENSUR |

1 |

EDAR Paine/Chile |

| ACCIONA AGUA |

1 |

EDAR EL QUIÑON |

| ACCIONA AGUA |

2 |

EDAR VILLAROBLEDO |

| ACCIONA AGUA |

2 |

ETAR CACIA |

| ACUAESTUDIOS |

1 |

Toro |

| ACUAESTUDIOS |

1 |

Trujillo |

| AGUAS FILTRADAS |

1 |

Depuradora Casino |

| ALCEDAR |

1 |

Alcorisa |

| ALTO TAJUÑA UTE |

2 |

ACT IV Cuenca Alta Río Tajuña |

| ARRUBAL Y AGONCILLO UTE |

2 |

EDAR Arrubal y Agondillo |

| ASTEISA |

1 |

EDAR Boecillo |

| ASTEISA |

1 |

Ribadeo |

| ASTEISA |

1 |

Valencia de Alcantara |

| ASTEISA |

1 |

EDAR Badarán |

| BABCKOX WILCOX |

1 |

Vall D'Uxo |

| COCETT |

1 |

Estación de Servicio Polaris |

| COLLOSA |

1 |

Cuellar |

| COMYLSA |

2 |

EDAR Sagunto |

| CONST. MOYUA/INITEC |

2 |

EDAR Zumaia |

| CONSTRUCCIONES GAMO |

1 |

Bombeo Aljaima |

| CONSTRUCCIONES SARRION |

4 |

EDAR'S Calatrava |

| CONSTRUCCIONES SARRION |

2 |

EDAR LA SAGRA |

| CONTRATAS LA MANCHA |

2 |

Depuradoras de Terrinches, Albadalejo y otras |

| COPISA |

2 |

EDAR Reinosa y Campoo de Emmedio |

| CTR SALAMANCA |

1 |

CTR SALAMANCA |

| CUBIERTAS |

1 |

C.P. Topas |

| CUBIERTAS |

1 |

Guadix |

| CUBIERTAS |

1 |

Zuera |

| CUBIERTAS |

1 |

Carcel de Huelva |

| CUBIERTAS |

1 |

EDAR Sanxenxo |

| DEBEOCAN |

2 |

EDAR BARRANCO SECO II - LAS PALMAS |

| DEMAIN |

1 |

EDAR Olloniego/Asturias |

| DEPURACION ZONA 7B UTE |

2 |

EDAR'S ZONA 7B DE ARAGON |

| DETELCA U.T.E. |

1 |

Potabilizadora Las Palmas |

| DINOTEC |

2 |

EDAR Quintana |

| DINOTEC |

1 |

EDAR Torredelcampo |

| DINOTEC |

1 |

EDAR Estepa |

| DINOTEC |

1 |

EDAR Benallup |

| DINOTEC |

2 |

EDAR SATOCAN (LAS PALMAS DE GRAN CANARIA) |

| DRACE MEDIOAMBIENTE |

1 |

EDAR ROBLEDILLO |

| DRACE MEDIOAMBIENTE |

1 |

EDAR BERZOSA |

| DRAGADOS |

1 |

CP ESTREMERA |

| DTD |

1 |

EDAR Isla Mayor |

| DTD |

1 |

EDAR San Roque |

| DTD |

1 |

COLECTOR Y EDAR DE ALOSNO / HUELVA |

| DTD |

1 |

EDAR CASTELLAR DE LA FRONTERA Y ALMORAIMA |

| DYTRAS |

1 |

Xinzo de Limia |

| DYTRAS |

1 |

Aeropuerto de G. Canaria |

| DYTRAS |

1 |

Fonsagrada |

| DYTRAS |

2 |

EDAR Palma del Rio / Córdoba |

| DYTRAS |

1 |

EDAR La Carolina / Jaén |

| DYTRAS |

1 |

EDAR Fines / Almeria |

| DYTRAS |

1 |

EDAR´S AVILA CEBREROS |

| DYTRAS |

1 |

EDAR PRIEGO CORDOBA |

| DYTRAS |

1 |

EDAR´S AVILA EL BARRACO |

| ECOPRENEUR CHILE |

1 |

EDAR Traiguén y Lumaco |

| ECOPRENEUR CHILE |

8 |

Calbuco, Frutillar, Los Muermos |

| ECOPRENEUR CHILE |

1 |

Huasco |

| ECOPRENEUR CHILE |

2 |

Essal Maullin |

| ECOTECNICA |

1 |

EDAR Bucelas |

| EDAR ALMAZAN UTE |

1 |

EDAR Almazán / Soria |

| EL PLANTIO UTE |

2 |

AMPL.Arroyo del Plantío |

| ELECNOR |

1 |

EDAR Cadreita |

| ENFECSA |

2 |

EDAR Rejas |

| EPTISA |

1 |

EDAR CUIÑA |

| ESPINA OBRAS HIDRAULICAS |

2 |

CIUDAD DE LA COSTA (URUGUAY) |

| FCC |

1 |

EDAR Sabadell |

| FCC |

1 |

Barranco Seco II |

| FCC |

1 |

EDAR Cordoba |

| FCC |

1 |

C.P. Albolote |

| FCC |

2 |

AMPLIACION EDAR CAMPO REAL |

| FCC/SPA |

1 |

EDAR Rejas |

| FERROVIAL AGROMAN |

2 |

EDAR Alcantarilla |

| GENERALITAT |

2 |

Canals D'Alcudia |

| GESPASER |

1 |

EDAR Ribarroja |

| GIA GRUPO EP |

1 |

EDAR Briviesca |

| GRUPO GENERALA |

2 |

HACIENDA RIQUELME |

| HIDROCONTRATO |

2 |

ETAR Da Boavista |

| HIDROCONTRATO |

1 |

ETAR Vidago |

| HLC |

2 |

EDAR en Portugal |

| IMFLUID |

1 |

EDAR Algarrobo |

| IMFLUID |

2 |

EDAR POL.JUNCARIL-ASEGRA ALBOROTE (GRANADA) |

| IMFLUID |

1 |

EDAR MARTOS |

| INFILCO |

2 |

Xátiva |

| INFILCO |

1 |

Cariñena |

| INFILCO |

2 |

EDAR PAZARDJIK |

| INFILCO |

2 |

EDAR Nord-oriental D'Andorra |

| INI MEDIOAMBIENTE |

1 |

EDAR Porreras |

| INITEK |

1 |

EDAR Ispaster/Vizcaya |

| INITEK |

1 |

Deba |

| INITEK |

1 |

EDAR La Puebla de la Barca |

| INITEK |

1 |

EDAR DE NANCLARES |

| INITEK |

1 |

EDAR RIVABELLOSA (ALAVA) |

| INTEIN |

1 |

Repsol Química |

| ISOLUX WAT |

2 |

EDAR Calasparra |

| ISOLUX WAT |

2 |

Viella |

| ISOLUX WAT |

2 |

EDAR Villaconejos |

| ISOLUX WAT |

1 |

EDAR Herencia |

| M.JOCA |

1 |

EDAR Valdelacalzada |

| MADESA |

1 |

Euromed |

| MEYDE |

1 |

Montoro / Cordoba |

| MP MEDIOAMBIENTE |

2 |

EDAR Curtidos Lorca |

| MP SERVICIOS INDUSTRIALES |

1 |

EDAR DE EL CUERVO - SEVILLA |

| NECSO |

1 |

C.P. Arajuez |

| NOCHE Y DIA |

1 |

Motilla |

| NOCHE Y DIA |

1 |

Bullas |

| NOCHE Y DIA |

2 |

Alcantarillas |

| OBRASCON HUARTE LAIN |

1 |

Tunel Ave Colmenar-Soto |

| OCP |

2 |

EDAR Denia |

| OCP |

1 |

Cabañas Pontedeume |

| ODEMAN |

1 |

EDAR Monesterio |

| OSEPSA |

2 |

EDAR Pliego/Murcia |

| PASSAVANT-COPASA |

1 |

EMISARIO Y EDAR VILLABRAZARO (ZAMORA) |

| PASSAVANT-COPASA |

2 |

EDAR LOS PEDROCHES |

| PRIDESA |

2 |

EDAR Cehegín |

| PRIDESA |

2 |

EDAR Almeria Este / El Toyo |

| PRIDESA |

1 |

EDAR Ciudadela/Menorca |

| PRIDESA |

1 |

EDAR Puente Genil |

| PRIDESA |

2 |

EDAR Tánger |

| PRIDESA |

1 |

EDAR Utrera |

| PRIDESA |

3 |

EDAR Osorno |

| RIEGOSUR |

2 |

EDAR Carmona |

| SACEEM |

1 |

DURAZNO |

| SADYT |

1 |

EDAR BURGUILLOS |

| SADYT |

1 |

EDAR POLAN |

| SAICO |

1 |

Tavernes |

| SERAGUA |

2 |

EDAR Rejas |

| SETA |

1 |

AOUJSA (TUNEZ) |

| SMYTA |

1 |

Navas del Rey |

| SOCAMEX, S.A. |

4 |

ACT. X Cuenca media Río Guadarrama |

| SOCAMEX, S.A. |

2 |

EDAR Guijuelo |

| SOCAMEX, S.A. |

1 |

Emisario y EDAR Tudela de Duero |

| SOCAMEX, S.A. |

1 |

EDAR Iscar |

| SOCAMEX, S.A. |

1 |

EDAR Soller |

| SOGEA, S.A. |

2 |

EDAR Freixo/Portugal |

| SPA, S.A. |

2 |

EDAR Callosa del Segura |

| TECNICAS REUNIDAS |

2 |

EDAR Majadahonda |

| TECNICAS REUNIDAS |

4 |

Guadalhorce |

| TECNICAS REUNIDAS |

1 |

EDAR CAÑADA DE GALLEGO T.M. MAZARRON (MURCIA) |

| TECYMED |

1 |

P.I. La Foya de Quartell |

| TECYMED |

1 |

EDAR Masia Bach |

| TECYMED |

1 |

EDAR Masia Baló |

| TECYMED |

1 |

EDAR Nova Panorámica Sant Jordi |

| TEYMA |

1 |

Ciudad de Canelones |

| TRITIO |

1 |

--- |

| TRITIO |

1 |

EDAR Platea / Teruel |

| UTE ABASTECIMIENTO PUERTOLLANO |

2 |

EDAR PUERTOLLANO - CIUDAD REAL |

| U.T.E. COLLOSA-SOCAMEX |

1 |

EDAR ASTORGA (LEON) |

| UTE AMPLIACION EL PLANTIO |

2 |

Arroyo del Plantio |

| UTE ARTZENTALES |

1 |

EDAR ARTZENTALES |

| UTE COMYLSA-DHA |

2 |

EDAR Xixona |

| UTE CONSTRUCTORA PEACHE |

1 |

EDAR MATAPOZUELOS |

| UTE CORONIL |

1 |

EDAR El Coronil |

| UTE EDAR BOADILLA |

2 |

EDAR Boadilla |

| UTE EDAR LANZAROTE |

1 |

EDAR Lanzarote |

| UTE EDAR OSUNA |

1 |

EDAR OSUNA |

| UTE EDAR SAN BARTOLOME |

1 |

EDAR SAN BARTOLOME DE LA TORRE |

| UTE ESTELLA |

2 |

EDAR Estella |

| UTE PAS-SPA |

1 |

EDAR Arenas de San Pedro |

| UTE PRIDESA-GRAMAN |

1 |

EDAR Borja |

| UTE PUERTO III DRAGADOS S.A. |

1 |

EDAR CP PUERTO III |

| UTE RIO TAJUÑA |

4 |

ACT. VI CYII - Río Tajuña |

| UTE SAN ESTEBAN DE GORMAZ |

1 |

EDAR San Esteban de Gormaz |

| UTE TECNICAS REUNIDAS S.A. TRIMTOR |

1 |

EDAR BARINAS (MURCIA) |

| UTE UICESA DHA |

1 |

EDAR CENTRO PENITENCIARIO ALBOCASSER |

| WAT |

1 |

EDAR Puleva |

The accumulation of solid waste in water treatment requires effective mechanized solutions for its extraction. FILTRAMAS, S.A. has a wide variety of equipment for the dragging of solid waste.

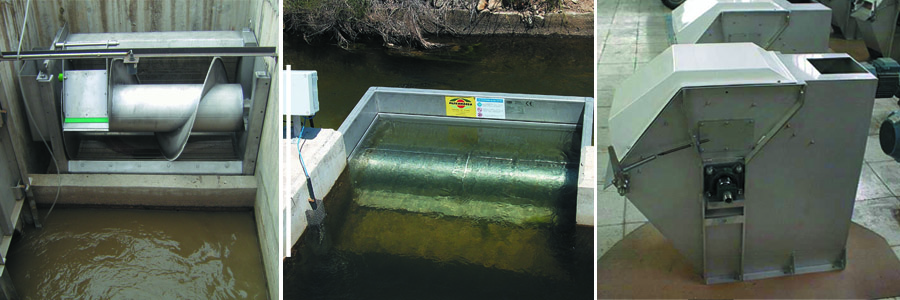

Band screens are those equipments, installed in a channel or , which has a series of filtering surfaces in continuous movement. Its mission is to extract the suspended solids of a certain size that accompany the effluent. There are several types of band screens, depending on the characteristics of the effluent and the installation:

The objective of this equipment is to protect the WWTP or pumping well from the possible arrival of large objects capable of causing obstructions in the different units of the installation. This operation consists of passing the waste water through a screen that separates and evacuates the bulky materials dragged along. They will retain large-sized solids such as branches, leaves, paper, tree roots, plastics, wipes, rags, etc., preventing damage and blockages to pumps, valves, pipes and other elements present in subsequent treatment processes of the purification plant.

These devices allow to continue filtering while performing self-cleaning, being especially suitable for those applications where continuous filtering is an important parameter of the process. Filtramas recommends the installation of its FB or FW in-line filters according to the flow and filtration needs.

Filter sieves offer high performance in the solid-liquid separation process. Our range of equipment responds to the different possible needs for each case.

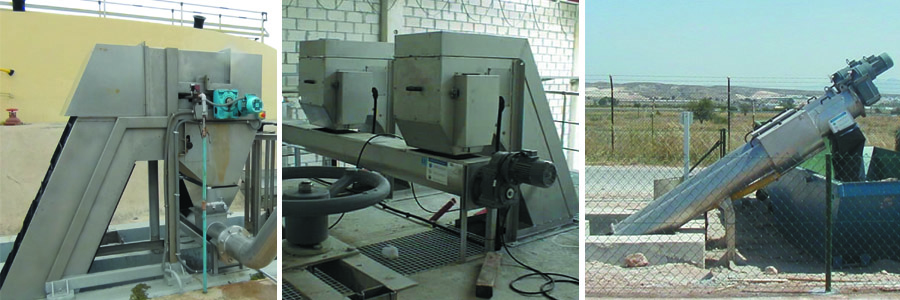

FILTRAMAS, S.A. has a wide range of solutions for the transport and compacting of the waste extracted by its machines, in a clean and discreet. The conveying and compacting systems can be with screws with final draining zone or hydraulic presses.

The conveyor-compactor screws supplied by FILTRAMAS, S.A., coupled together with its equipment, allow us to obtain a totally clean and fair-faced installation. The screw loading openings are designed for coupling to the discharge opening of the extraction equipment (bars movable grilles or screens), and the intermediate spaces are covered by a fairing.

In any water treatment or purification plant, there is a continuous need to isolate or regulate the flow of water in the channels and manholes or holes in walls (wall gates). This function is carried out by means of the placement of gates and cofferdams.

The result of our experience is the establishment of a standardization that determines a satisfactory result with a simple construction. For this reason, Filtramas has been developing the manufacture of penstocks and flashboards.

Filtramas manufactures channel hatches, wall hatches and cofferdams for different applications and uses.

The accumulation of solid waste in water treatment requires effective mechanized solutions for its extraction. FILTRAMAS, S.A. has a wide variety of equipment for the dragging of solid waste.

In the biological treatment of wastewater, a series of processes are generated based on the cultivation of bacterial microorganisms for the elimination of organic matter, nitrogen and phosphorus. It is one of the most common treatments for its simplicity and low cost.

FILTRAMAS, S.A. has a wide variety of equipment for bacterial culture applied to the treatment of urban and industrial wastewater.

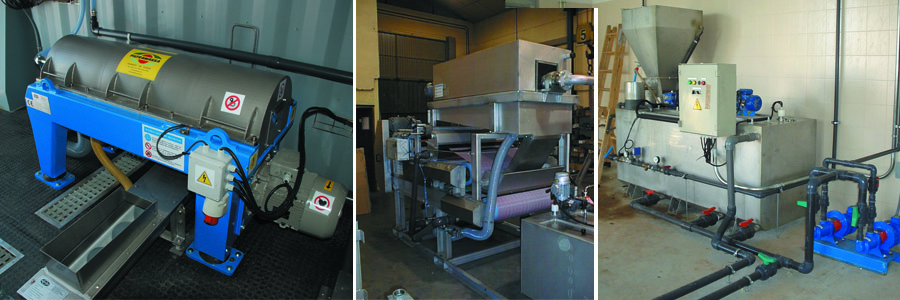

The dewatering of sludge is an essential process in the management of solid waste generated in water treatment. FILTRAMAS, S.A. offers different mechanized solutions to the problem according to the different possible needs.

FILTRAMAS S.A. has a wide variety of solutions for all kinds of problems associated with the treatment and cleaning of water, mud and sand. We develop our specialisation on the basis of the experience accumulated by our professionals, constant effort and close collaboration with our clients. FILTRAMAS S.A. perfects new products, looking for economic and effective solutions. Any problem that arises in the handling of fluids is carefully analyzed in order to find an economically balanced solution.