TRAVELING SCREEN> Microscreen

INTRODUCTION:

Micro filtration is a physical separation process in which the size of the passing light determines the degree of removal of dissolved solids, turbidity and microorganisms. Particles larger than the throughput of the filter screen are completely retained, although the accumulation of solids on the belt surfaces creates a “filter pad” capable of holding smaller particles than the throughput of the filter screen.

Micro sizing is a simple and widely proven filtration method that can be used to remove microscopic or larger particles, achieving a virtually solids-free effluent and a significant reduction in the oxygen demand associated with the pollutant load.

DESCRIPTION:

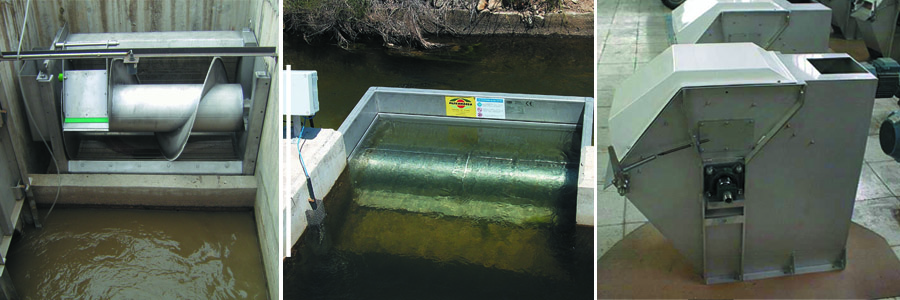

The FILTRAMAS, S.A. rotary micro sieve is a compact and very robust equipment that requires minimum maintenance; it consists of a cylinder horizontally assembled, covered with filtering panels. These panels are composed of a support mesh and a perfectly stretched microscopic mesh, which can be made of stainless steel, polyester, nylon or other materials.

The water to be treated enters the filter mesh so that any solid larger than the passage light is retained inside the drum. The cleaning of the mesh is carried out by means of a pressurized water washing system. The waste water is collected in an inner hopper and is piped out for further treatment. The moving parts of the unit are sealed by mechanical lock with a sliding seat made of NBR on stainless steel, which is subjected to positive pressure at all times.

The rotary micro sieve of FILTRAMAS, S.A. has the following CHARACTERISTICS:

-

Compact and robust design that minimizes maintenance.

-

The available step lights are 100-15 microns depending on the application.

-

Available in two versions, for installation in civil works or in containers.

-

Suitable for filtration of small particles.

-

Gravity filtration that minimizes energy costs.

-

Continuous operation even during the washing phase.

-

Washing system with pressurized water (3 bar).

-

Easy operation and maintenance.

APPLICATIONS:

-

Removal of solids from the effluent of the secondary decanters and a large part of the BOD/DQO load, reducing the associated oxygen demand.

-

Tertiary treatment prior to disinfection and prior to direct discharge to watercourses or underwater outfalls.

-

Ideal treatment in urban and industrial wastewater reuse applications.

-

Removal of fibers and hairs from urban and industrial water.

-

Microscreening to ensure the proper functioning of membrane bioreactor (MBR) plants.

-

Process water treatment in industry.

-

Drinking water treatment.

-

Fish farms.

GENERAL DIMENSIONS:

|

CLIENTE / CUSTOMER |

CANT./QTY |

PROYECTO / PROJECT |

| SETA |

1 |

CIUDAD DE BOACO - NICARAGUA |

| SOCAMEX |

1 |

EDAR SOLLER |

| SANCHEZ Y LAGO |

1 |

EDAR LA FRANCA |

Band screens are those equipments, installed in a channel or , which has a series of filtering surfaces in continuous movement. Its mission is to extract the suspended solids of a certain size that accompany the effluent. There are several types of band screens, depending on the characteristics of the effluent and the installation:

Band screens are those equipments, installed in a channel or , which has a series of filtering surfaces in continuous movement. Its mission is to extract the suspended solids of a certain size that accompany the effluent. There are several types of band screens, depending on the characteristics of the effluent and the installation:

The objective of this equipment is to protect the WWTP or pumping well from the possible arrival of large objects capable of causing obstructions in the different units of the installation. This operation consists of passing the waste water through a screen that separates and evacuates the bulky materials dragged along. They will retain large-sized solids such as branches, leaves, paper, tree roots, plastics, wipes, rags, etc., preventing damage and blockages to pumps, valves, pipes and other elements present in subsequent treatment processes of the purification plant.

These devices allow to continue filtering while performing self-cleaning, being especially suitable for those applications where continuous filtering is an important parameter of the process. Filtramas recommends the installation of its FB or FW in-line filters according to the flow and filtration needs.

Filter sieves offer high performance in the solid-liquid separation process. Our range of equipment responds to the different possible needs for each case.

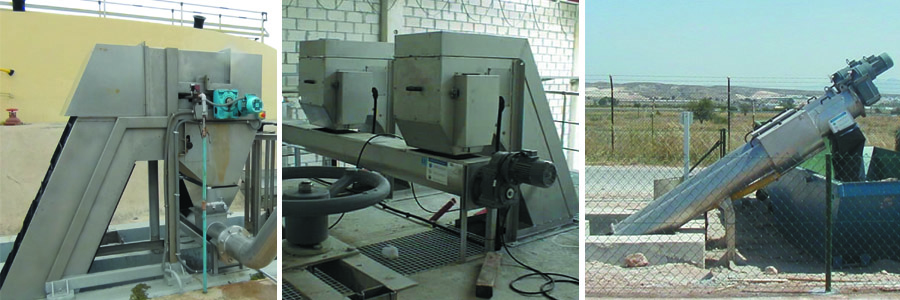

FILTRAMAS, S.A. has a wide range of solutions for the transport and compacting of the waste extracted by its machines, in a clean and discreet. The conveying and compacting systems can be with screws with final draining zone or hydraulic presses.

The conveyor-compactor screws supplied by FILTRAMAS, S.A., coupled together with its equipment, allow us to obtain a totally clean and fair-faced installation. The screw loading openings are designed for coupling to the discharge opening of the extraction equipment (bars movable grilles or screens), and the intermediate spaces are covered by a fairing.

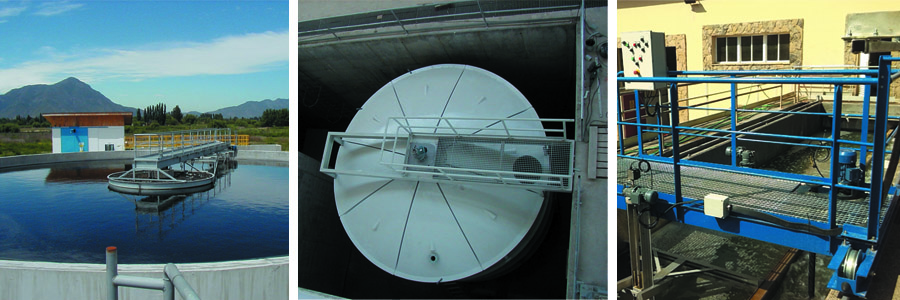

In any water treatment or purification plant, there is a continuous need to isolate or regulate the flow of water in the channels and manholes or holes in walls (wall gates). This function is carried out by means of the placement of gates and cofferdams.

The result of our experience is the establishment of a standardization that determines a satisfactory result with a simple construction. For this reason, Filtramas has been developing the manufacture of penstocks and flashboards.

Filtramas manufactures channel hatches, wall hatches and cofferdams for different applications and uses.

The accumulation of solid waste in water treatment requires effective mechanized solutions for its extraction. FILTRAMAS, S.A. has a wide variety of equipment for the dragging of solid waste.

In the biological treatment of wastewater, a series of processes are generated based on the cultivation of bacterial microorganisms for the elimination of organic matter, nitrogen and phosphorus. It is one of the most common treatments for its simplicity and low cost.

FILTRAMAS, S.A. has a wide variety of equipment for bacterial culture applied to the treatment of urban and industrial wastewater.

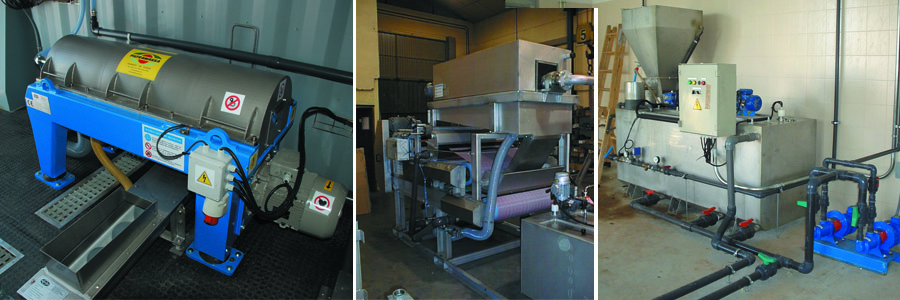

The dewatering of sludge is an essential process in the management of solid waste generated in water treatment. FILTRAMAS, S.A. offers different mechanized solutions to the problem according to the different possible needs.

FILTRAMAS S.A. has a wide variety of solutions for all kinds of problems associated with the treatment and cleaning of water, mud and sand. We develop our specialisation on the basis of the experience accumulated by our professionals, constant effort and close collaboration with our clients. FILTRAMAS S.A. perfects new products, looking for economic and effective solutions. Any problem that arises in the handling of fluids is carefully analyzed in order to find an economically balanced solution.